Menu

2.3 Gantry components

Download

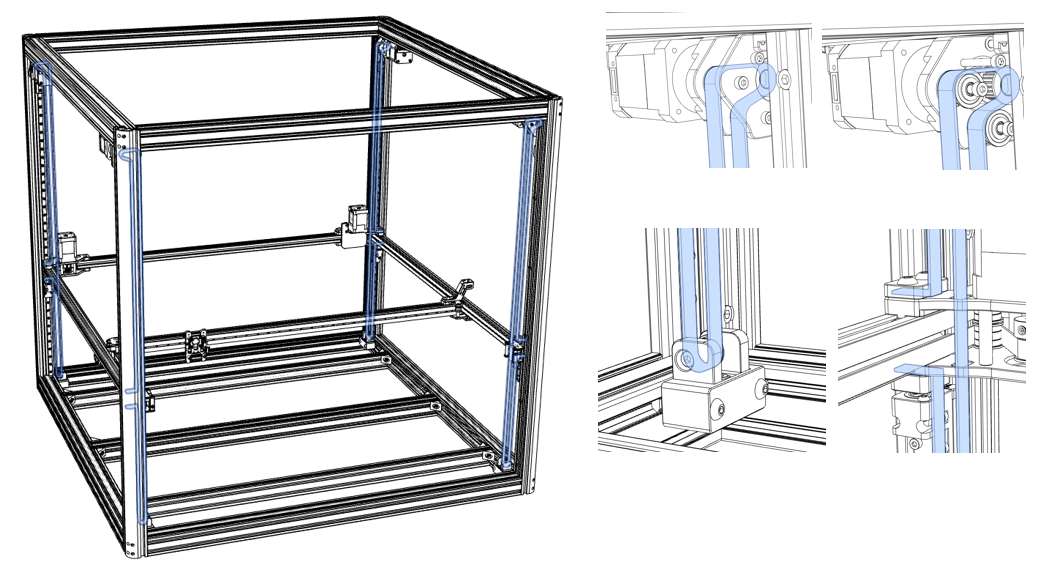

2.3 Gantry components

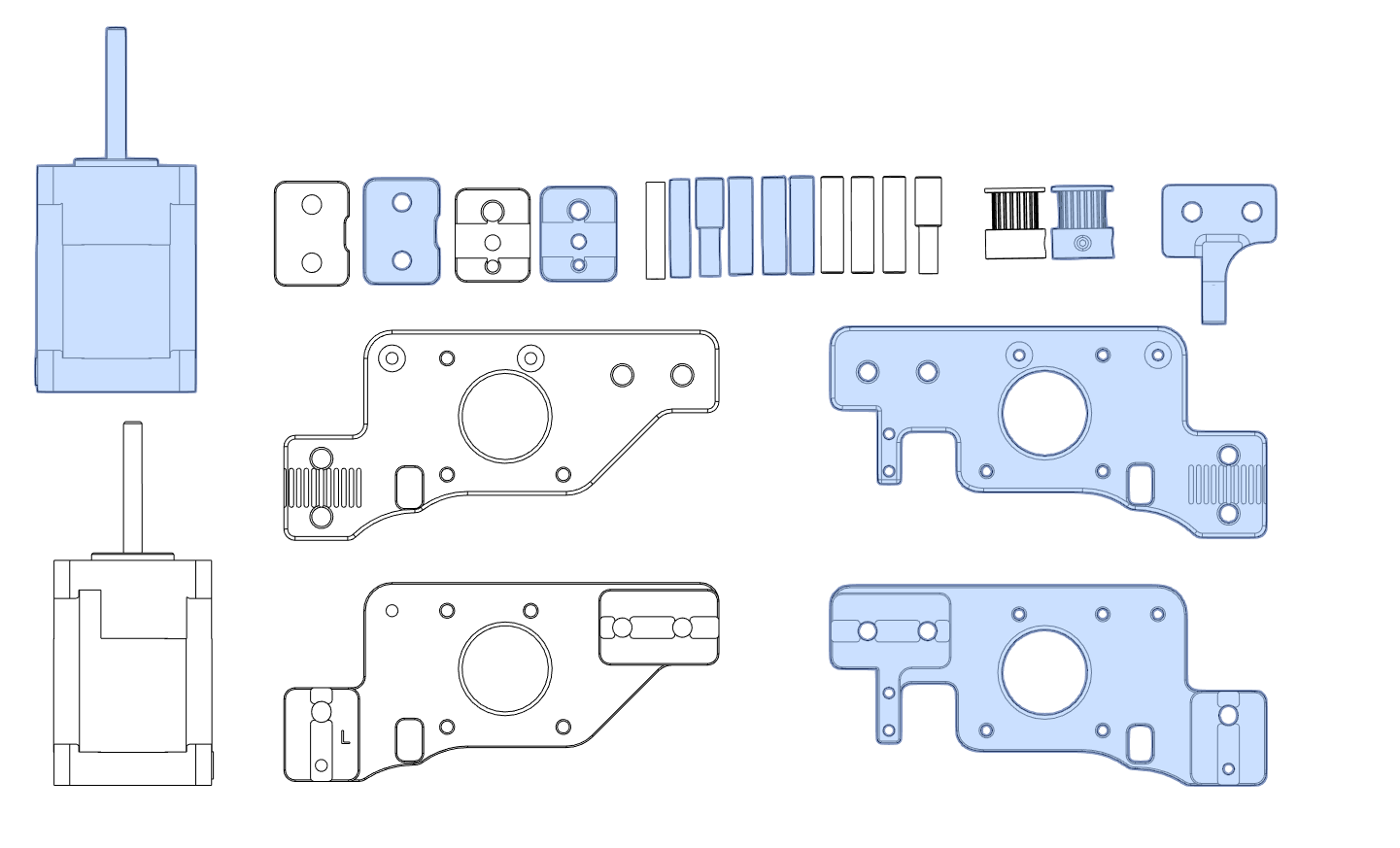

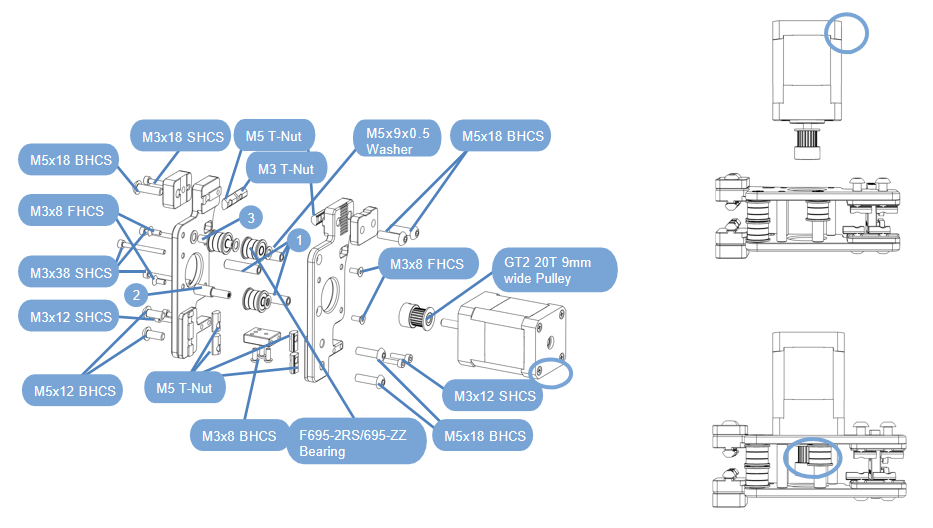

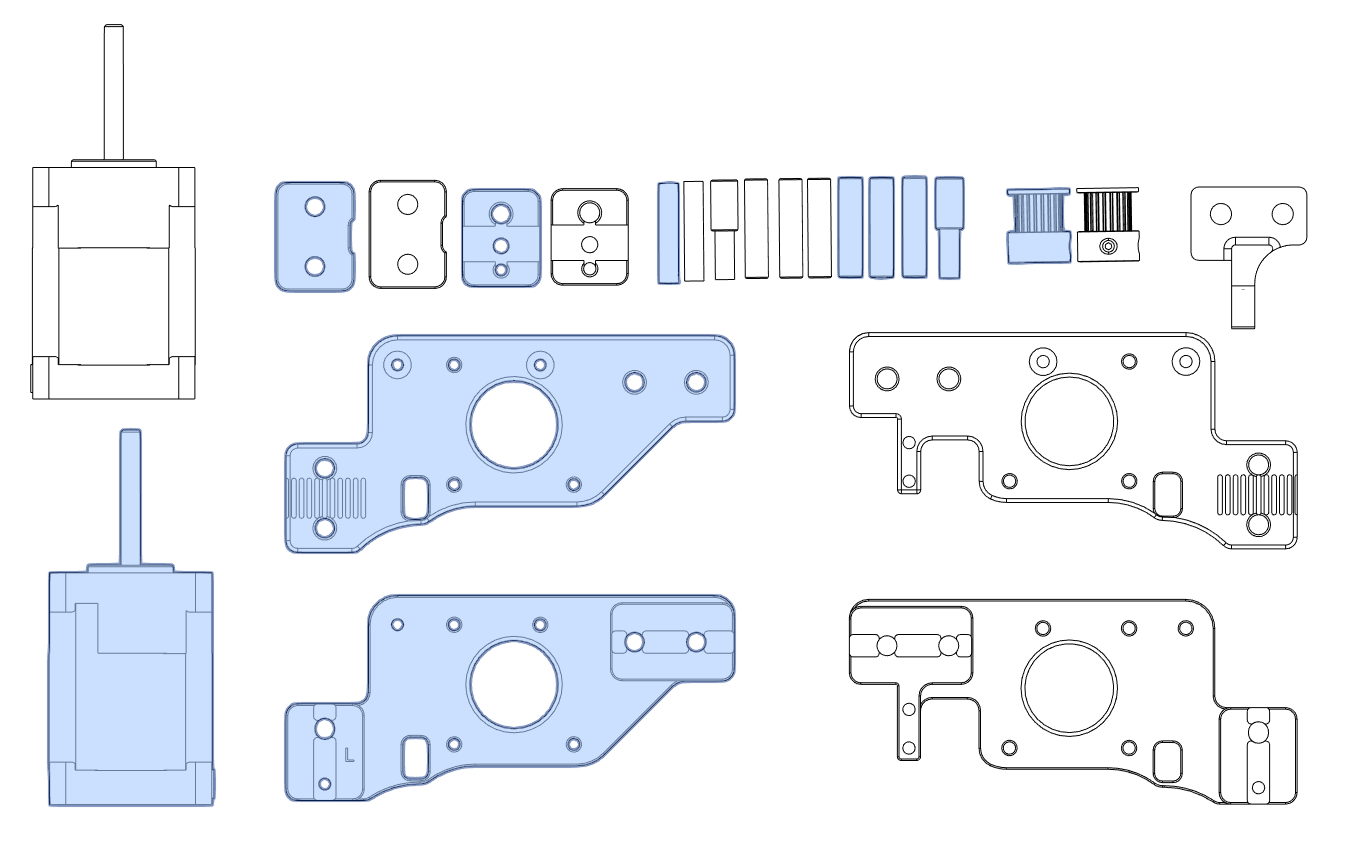

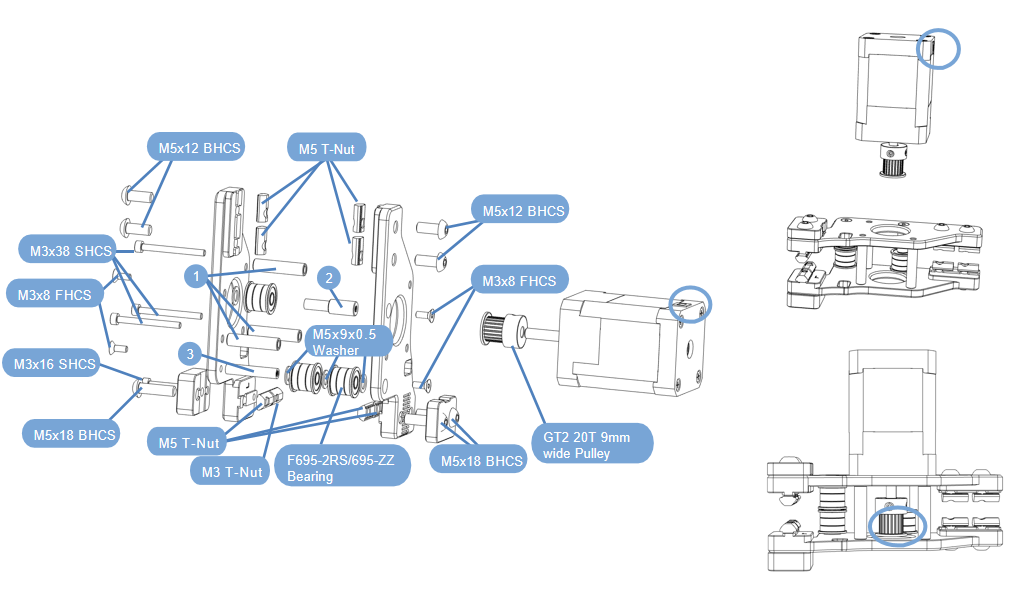

2.3.1 A Motor assembly

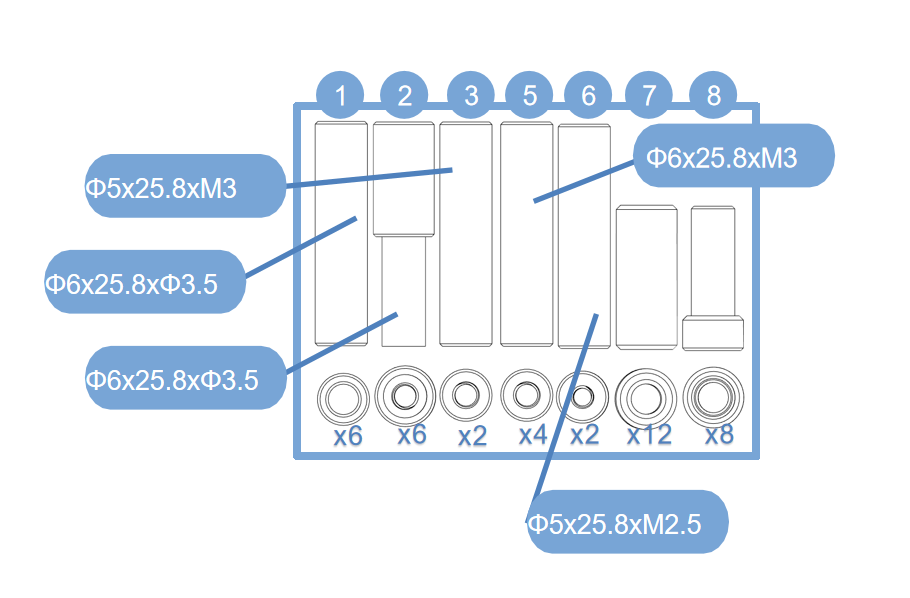

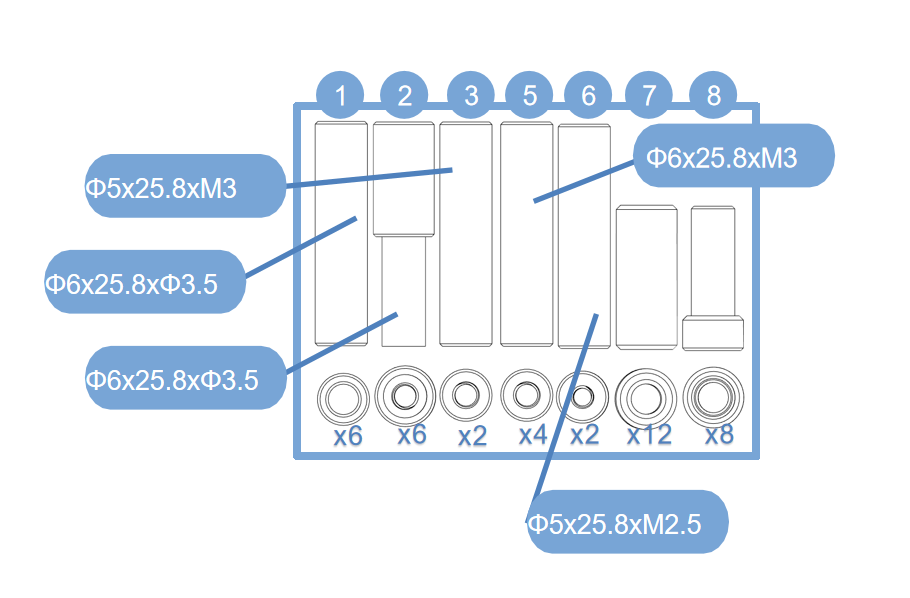

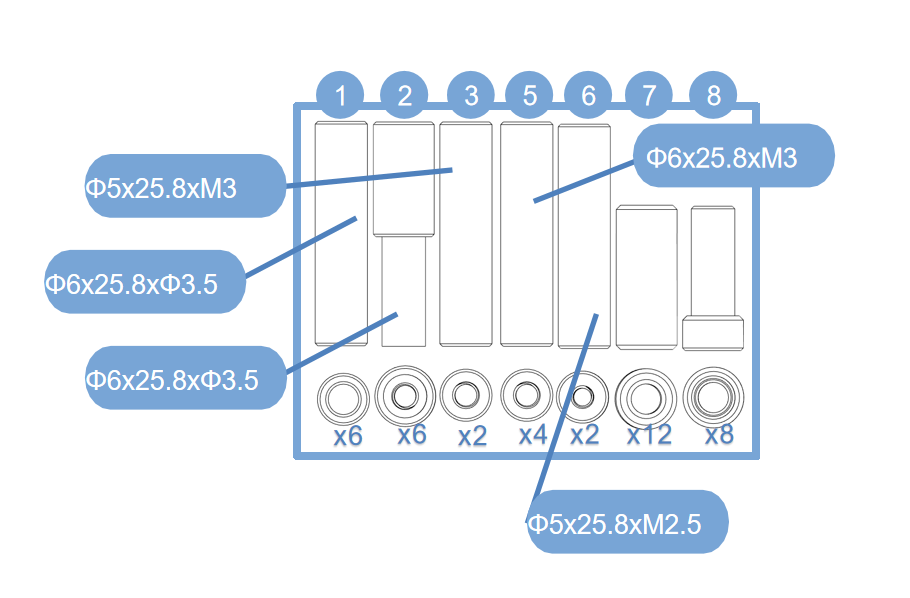

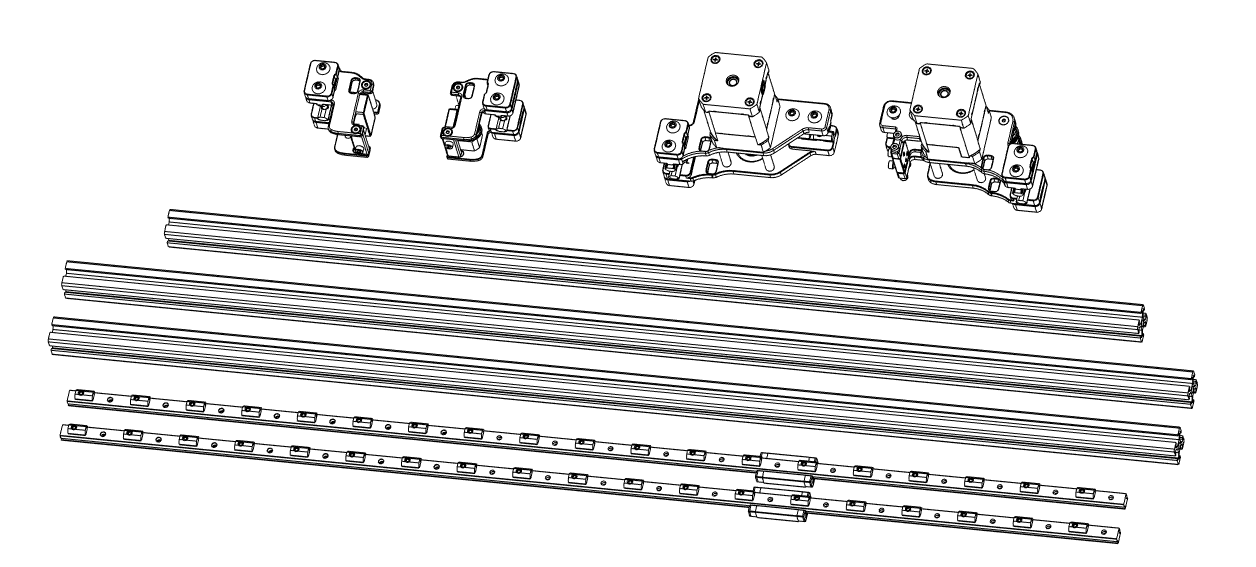

- Material preparation

- Prepare the materials as shown in the figure;Use screws to assemble them;

- Finally, use M3x38 screws to fix the motor;Pay attention to the direction of the motor wiring port.

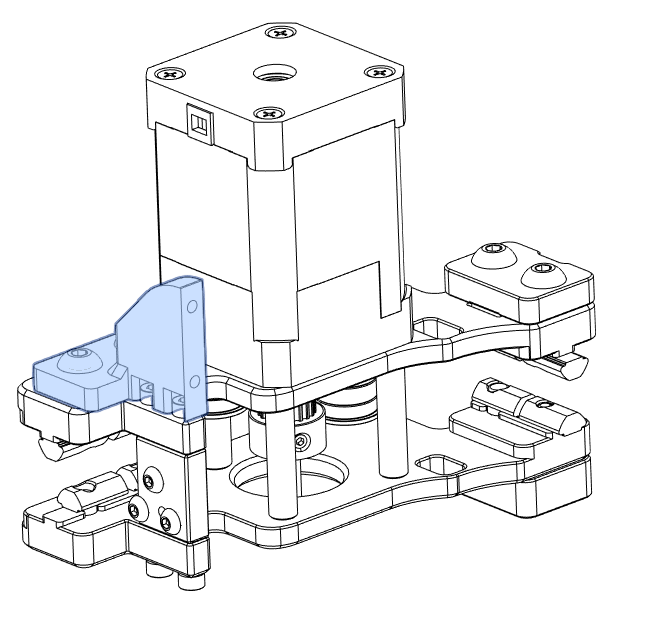

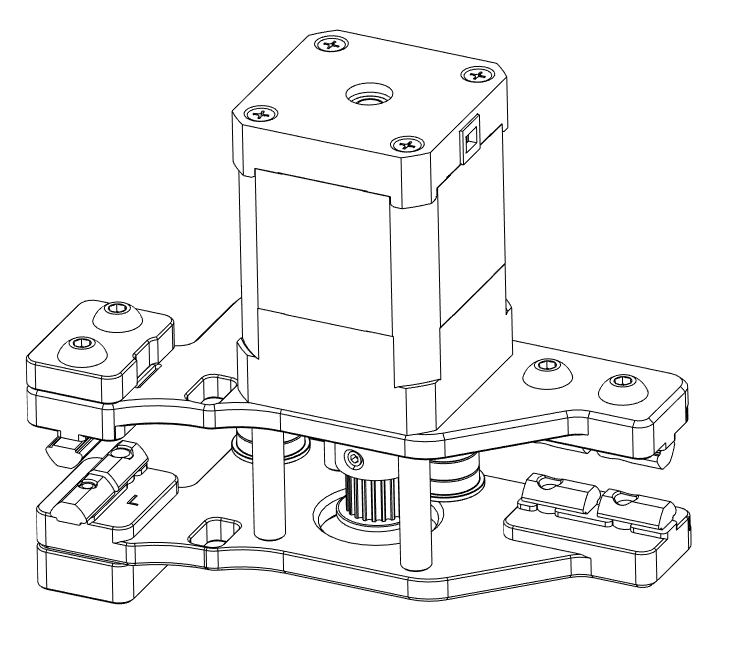

- Check work:Compare your assembled part to the graphic shown here;Pay attention to the pulley orientation and alignment with the bearing stack ups.

2.3.2 B Motor assembly

- Material preparation

- Prepare the materials as shown in the figure;Use screws to assemble them;

- Finally, use M3x38 screws to fix the motor;Pay attention to the direction of the motor wiring port.

- Check work:Compare your assembled part to the graphic shown here;Pay attention to the pulley orientation and alignment with the bearing stack ups.

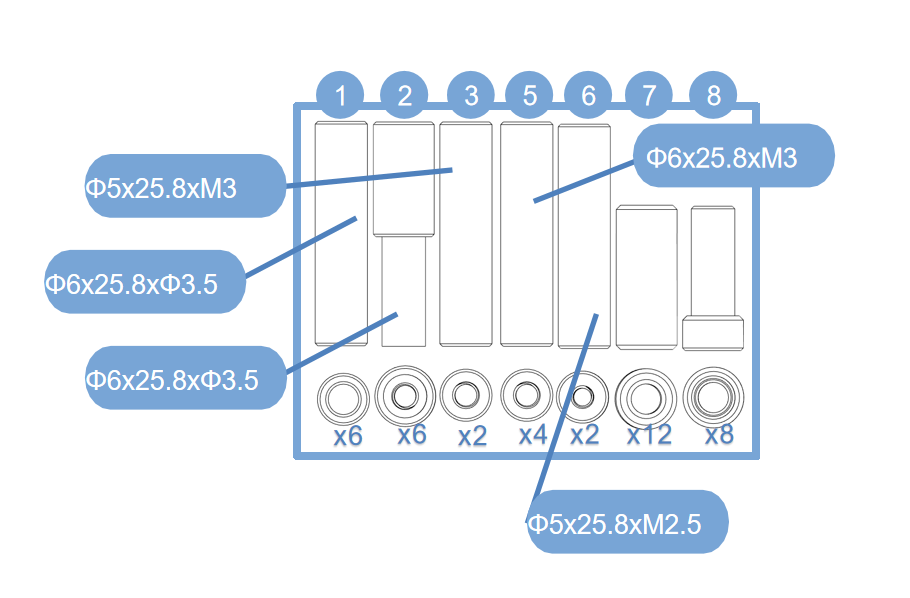

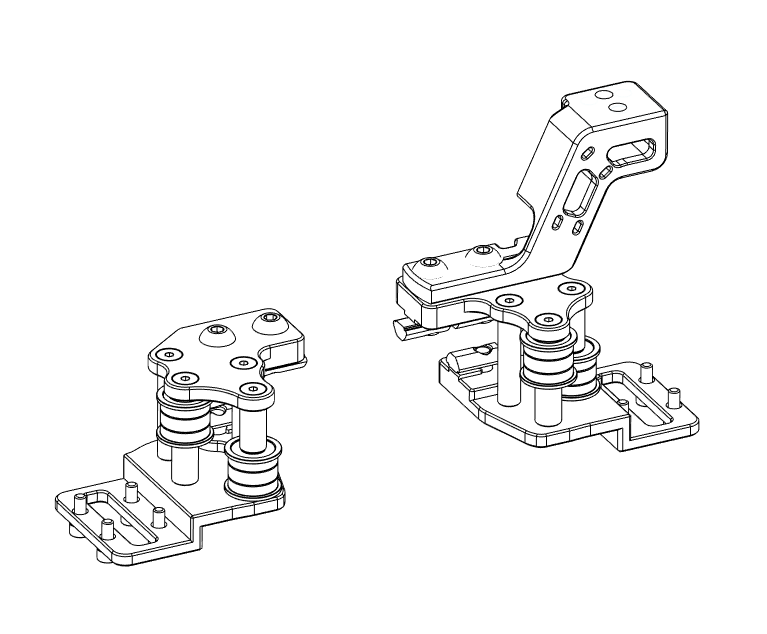

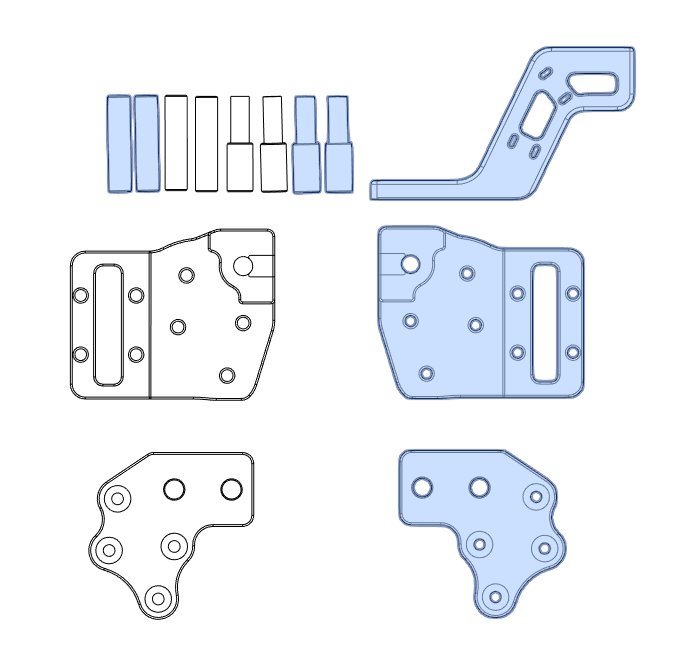

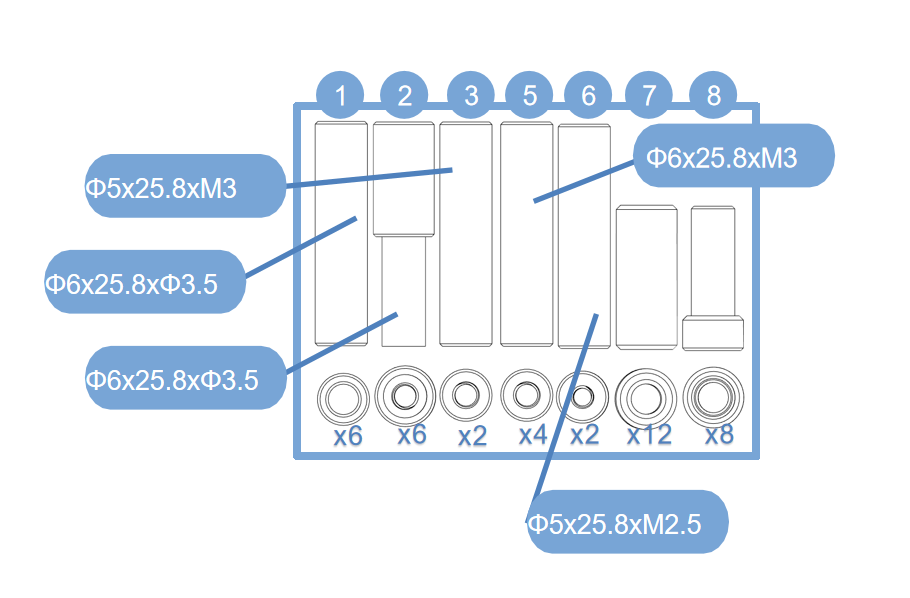

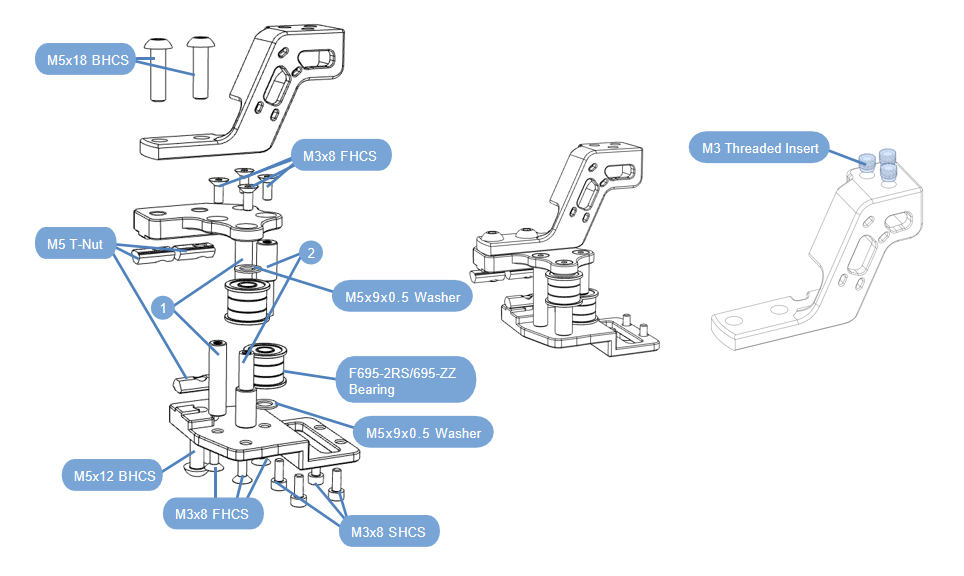

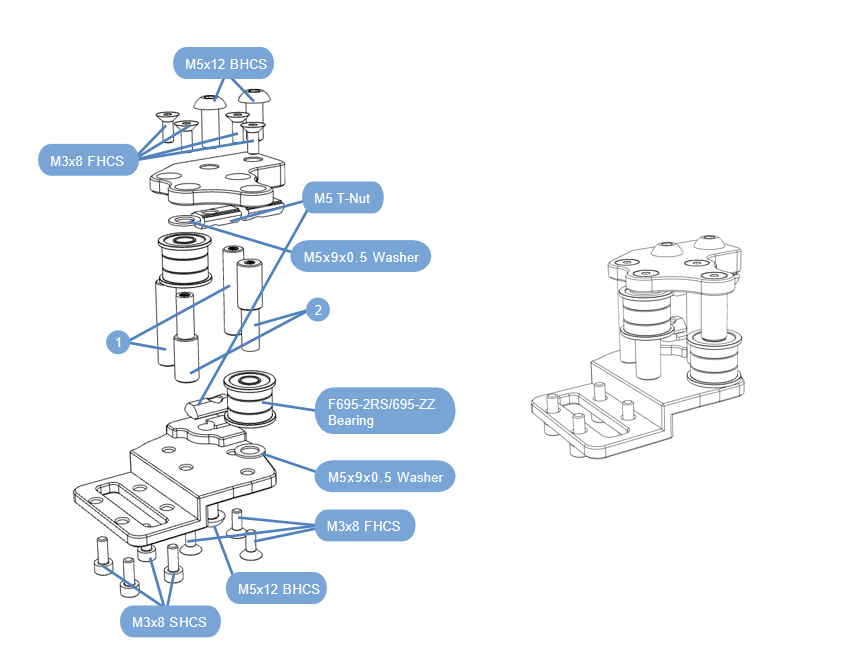

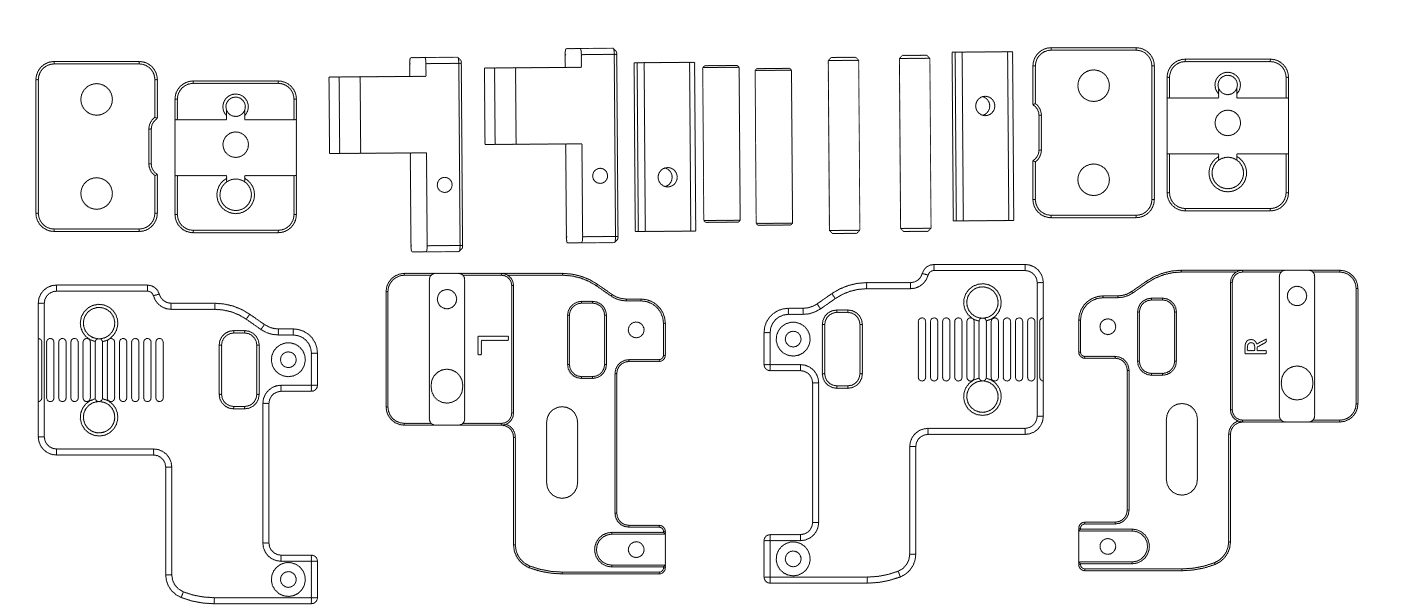

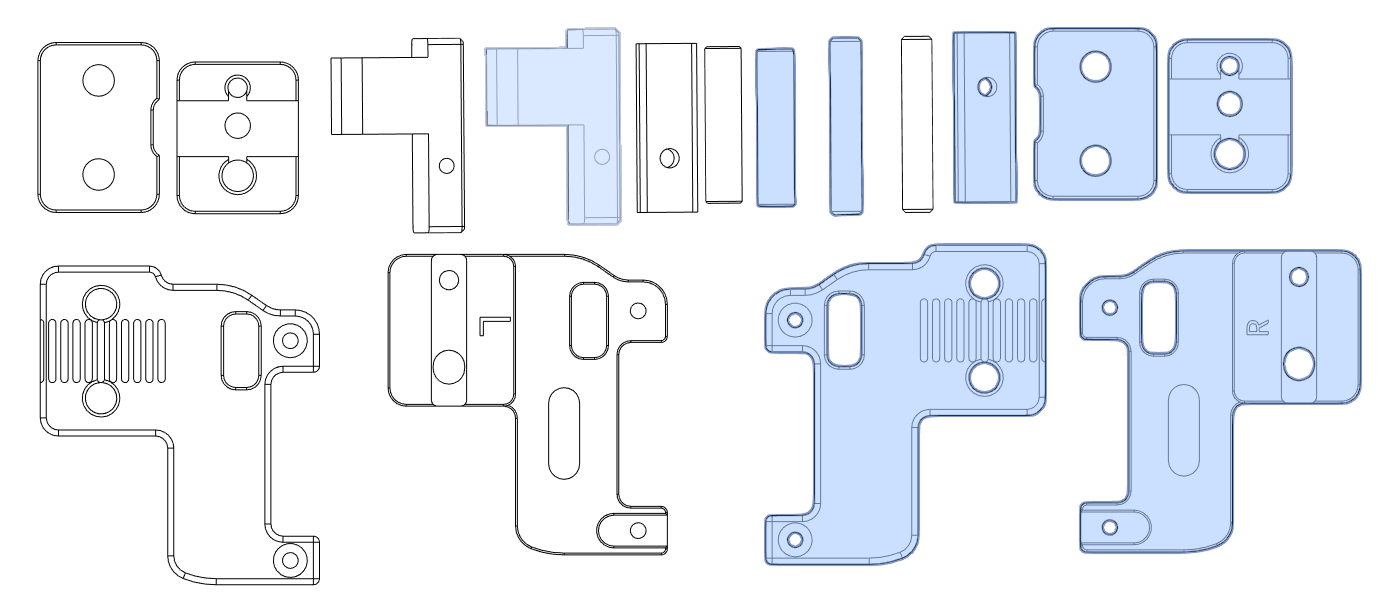

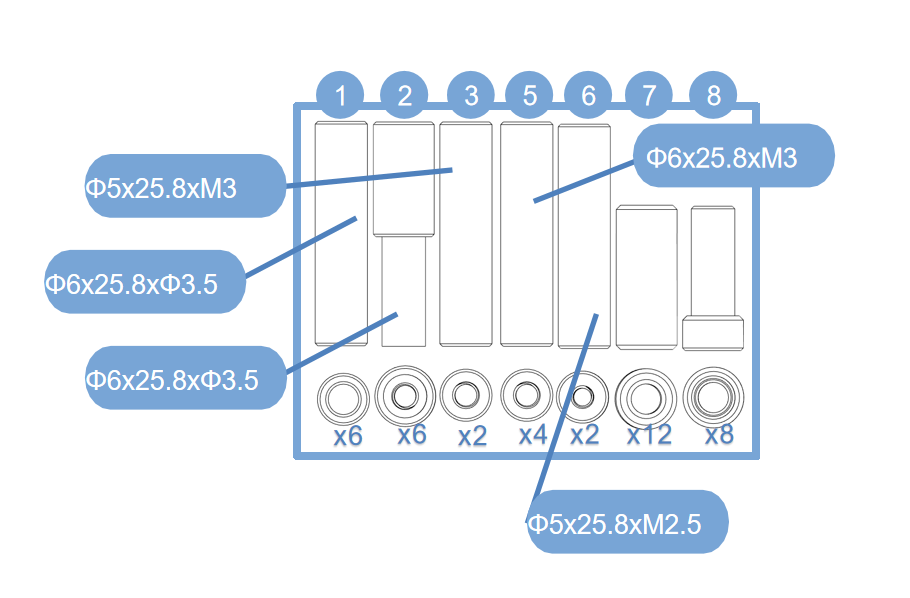

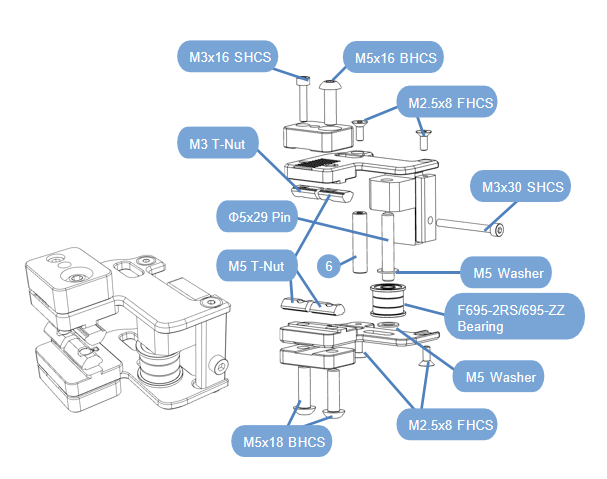

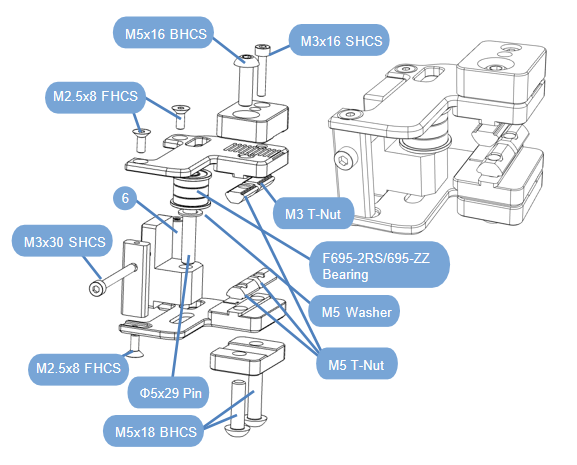

2.3.3 XY joint component

-

Material preparation

XY joint component-right

-

Material preparation

-

Use screws to assemble them,Be careful not to tighten all the screws.

NOTE: The bearing can be replaced with a timing belt idler pulley.

XY joint component-left

-

Material preparation

-

Use screws to assemble them,Be careful not to tighten all the screws.

NOTE: The bearing can be replaced with a timing belt idler pulley.

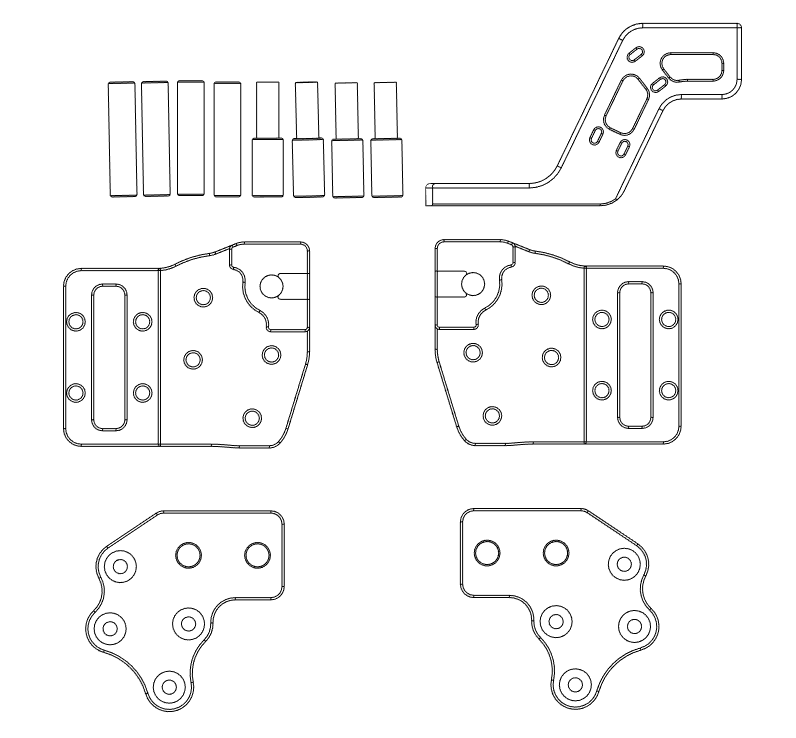

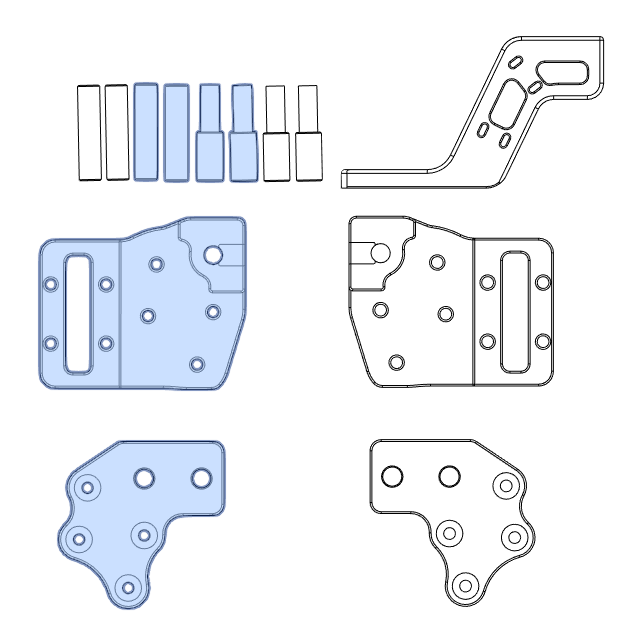

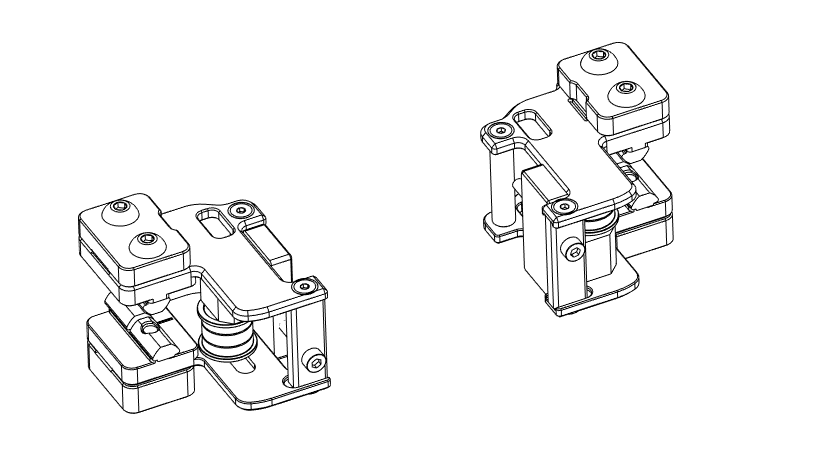

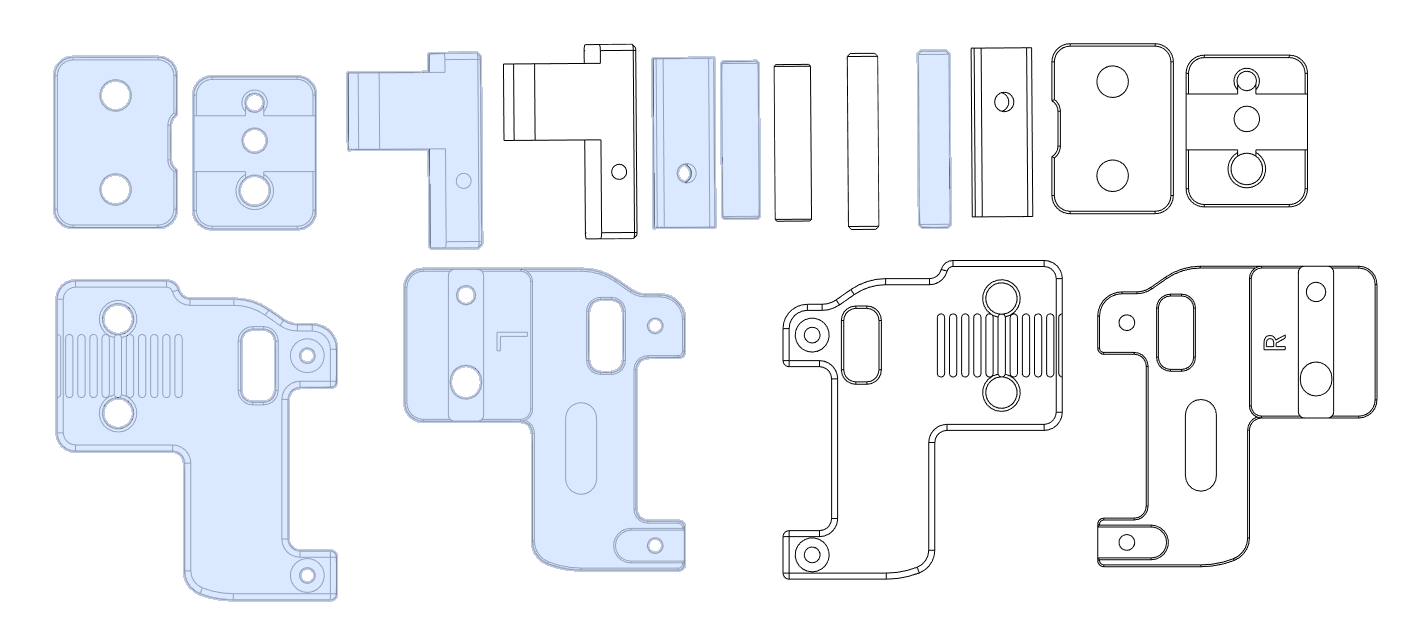

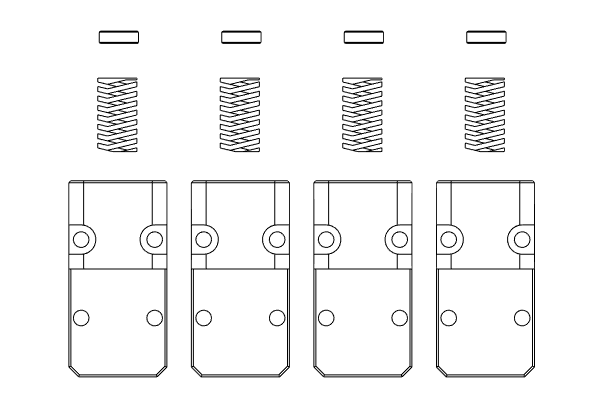

2.3.4 AB Idler Assembly

-

Material preparation

AB Idler Assembly-right

- Material preparation

- Use screws to assemble them,Be careful not to tighten all the screws.

AB Idler Assembly-left

- Material preparation

- Use screws to assemble them,Be careful not to tighten all the screws.

- Material preparation

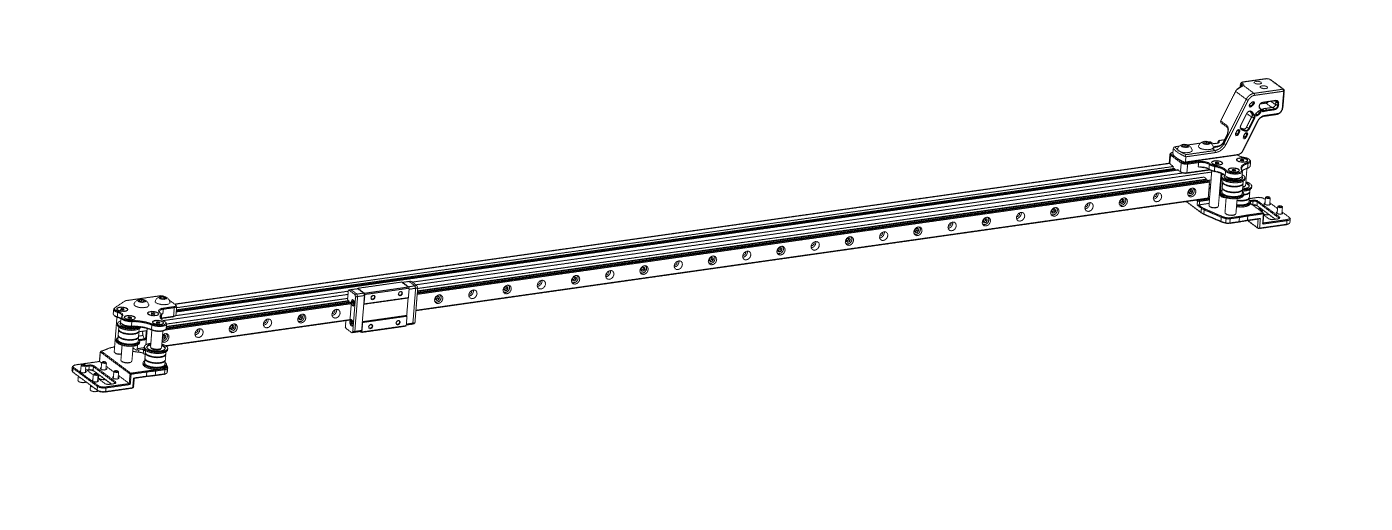

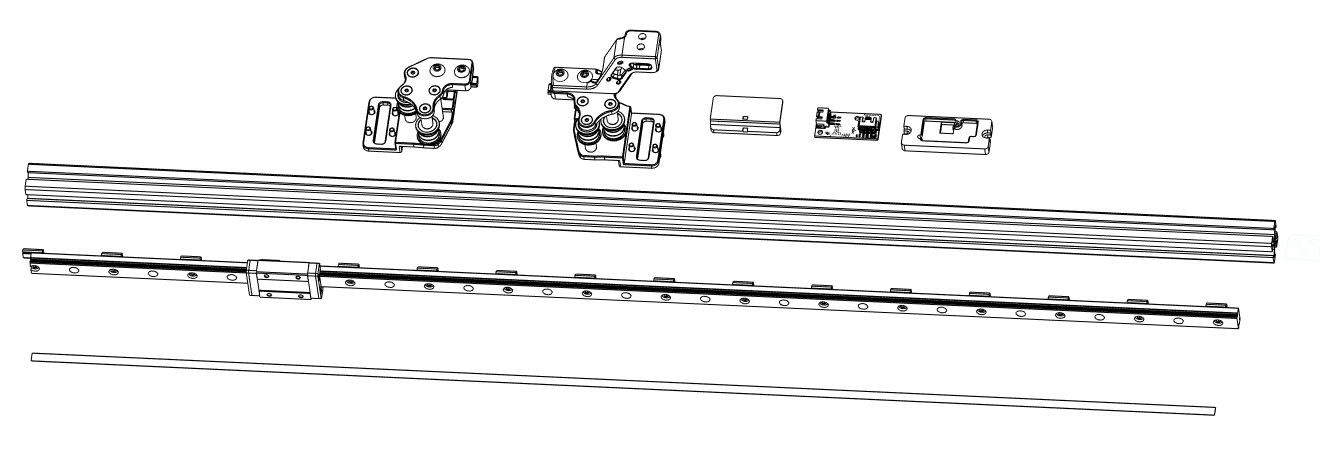

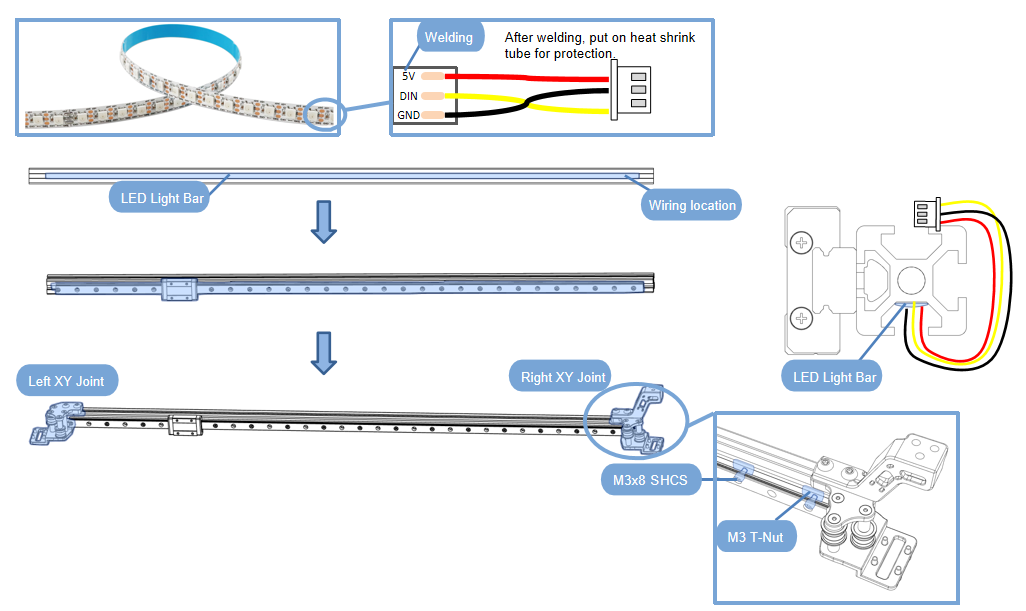

2.3.5 X-axis assembly

- Material preparation

- First, solder the connecting wire at one end of the light strip (refer to the wiring diagram for wiring);Insert the light strip into the profile and stick it in the center;

- Install 1 Pcs linear guide MGN12H (length 765mm) on the side of the profile,Use M3x8 FHCS for fixing;

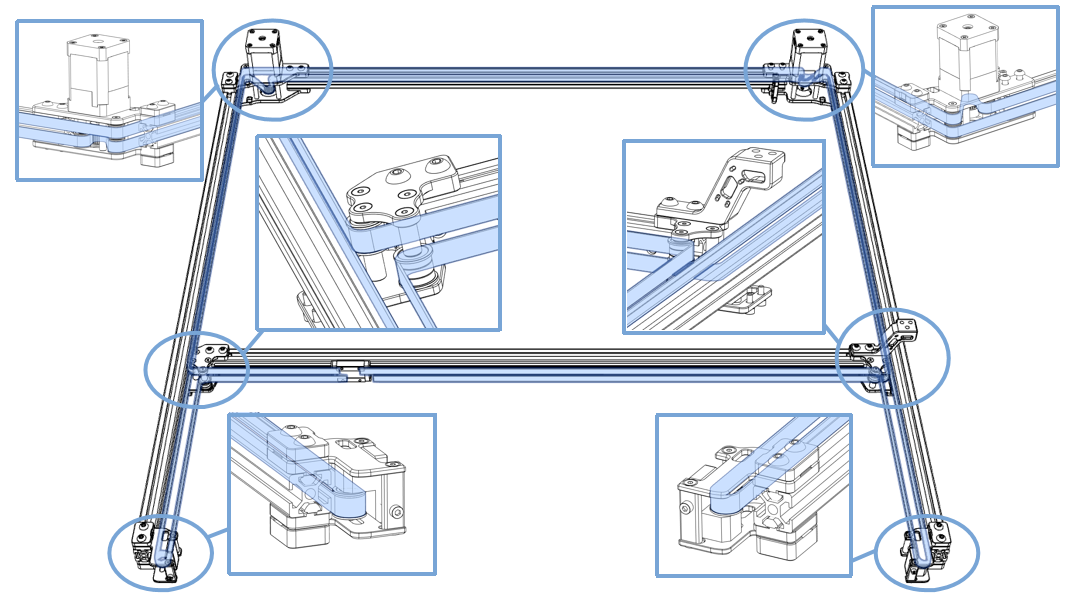

- Install the left/right XY joints on both sides of the profile and tighten the screws (make sure the light bar is on the bottom).

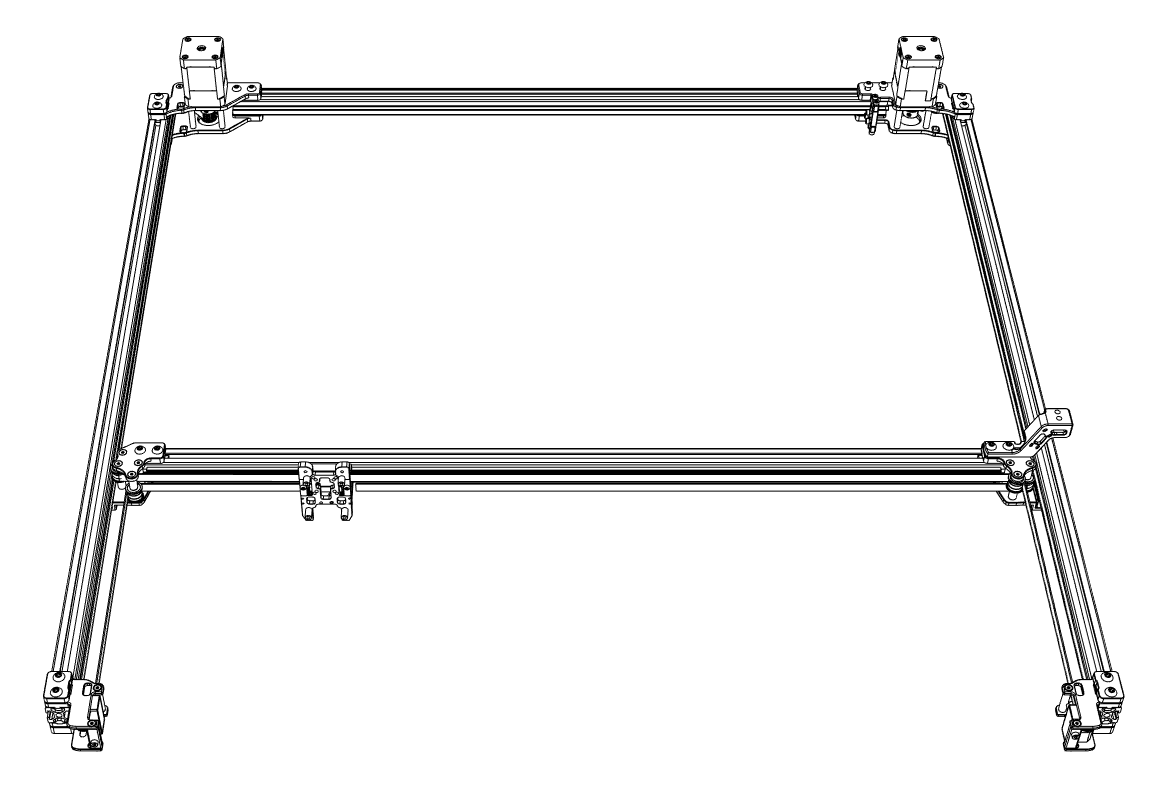

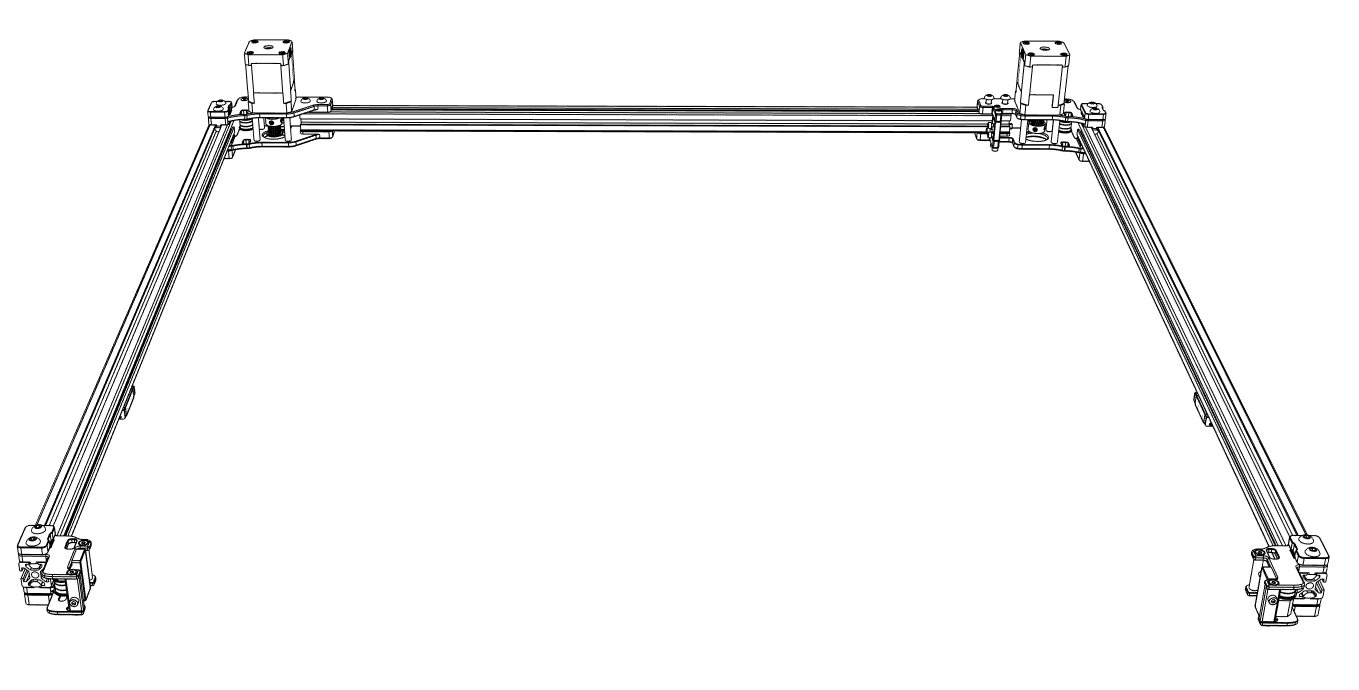

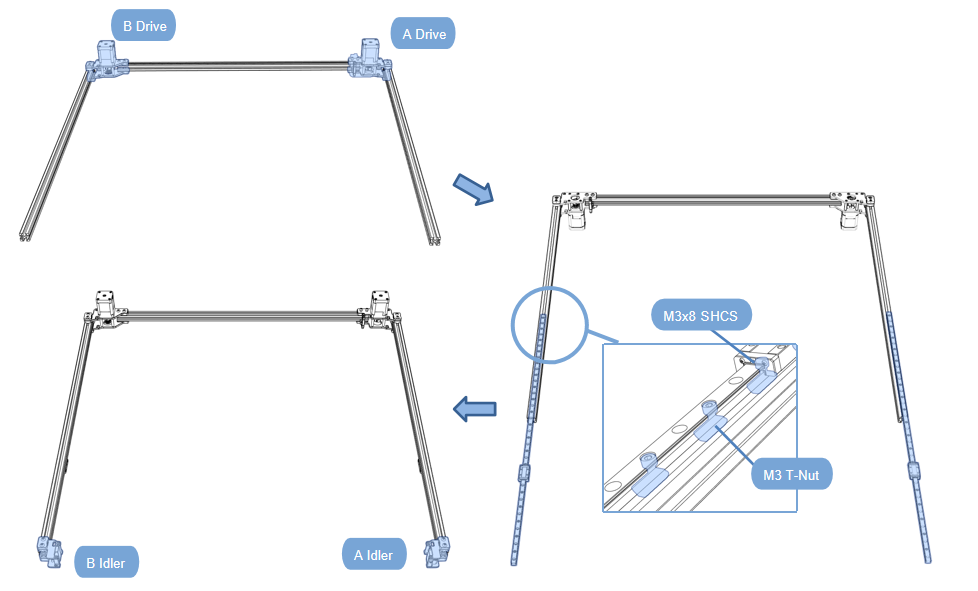

2.3.6 Y-axis assembly

- Material preparation

-First install the AB motors onto the profile (two profiles of the same length are Y); - Insert the screwed guide rail from one end of the profile (MGN9H length 760mm,2PCS),Use M3x8 FHCS for fixing,locking screw;

- Finally install the AB idler assembly;Tighten all parts screws.

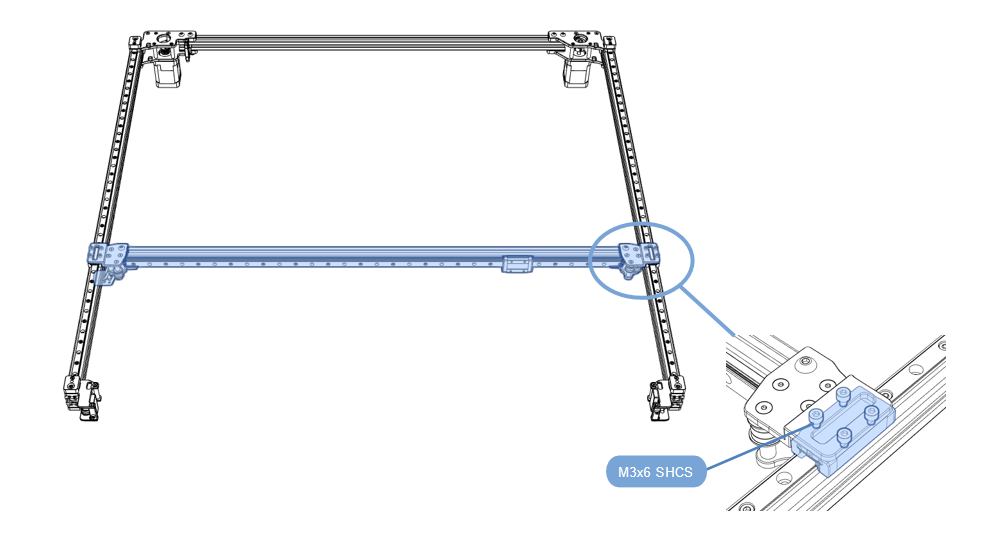

X-axis installation

- Install the previously assembled X-axis assembly onto the Y-axis assembly using the SHCS M3x6mm;

- Tighten all parts screws.

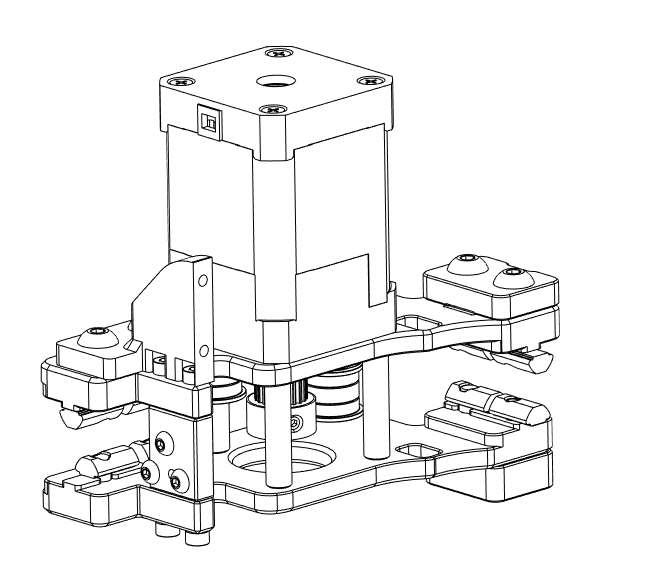

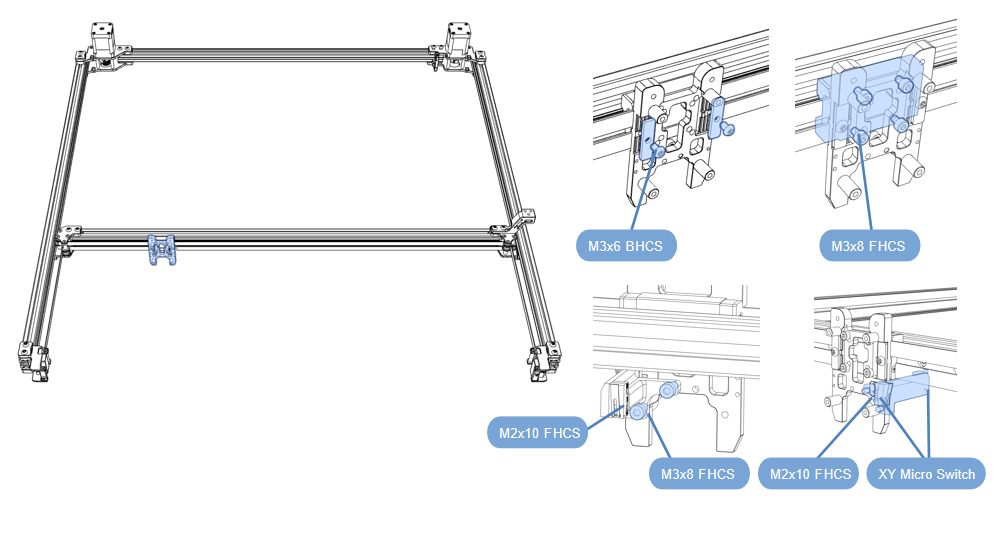

2.3.7 XY Belt, IDM bracket installation

XY Belt

- Install the belt as shown;

IDM bracket installation

- After the belt is put on, use Cartographer CNC toolhead to fix it, and use M3x6 BHCS to tighten the belt;Use M3x8 FHCS to fix the IDM ScannerCNC metal parts on the guide rail slide;

- Use M2x10 FHCS to fix 1 Pcs of micro switches on the printed part and 1 Pcs on the metal part;Install the micro switch print on the IDM ScannerCNC metal part and fix it with M3x8 FHCS;

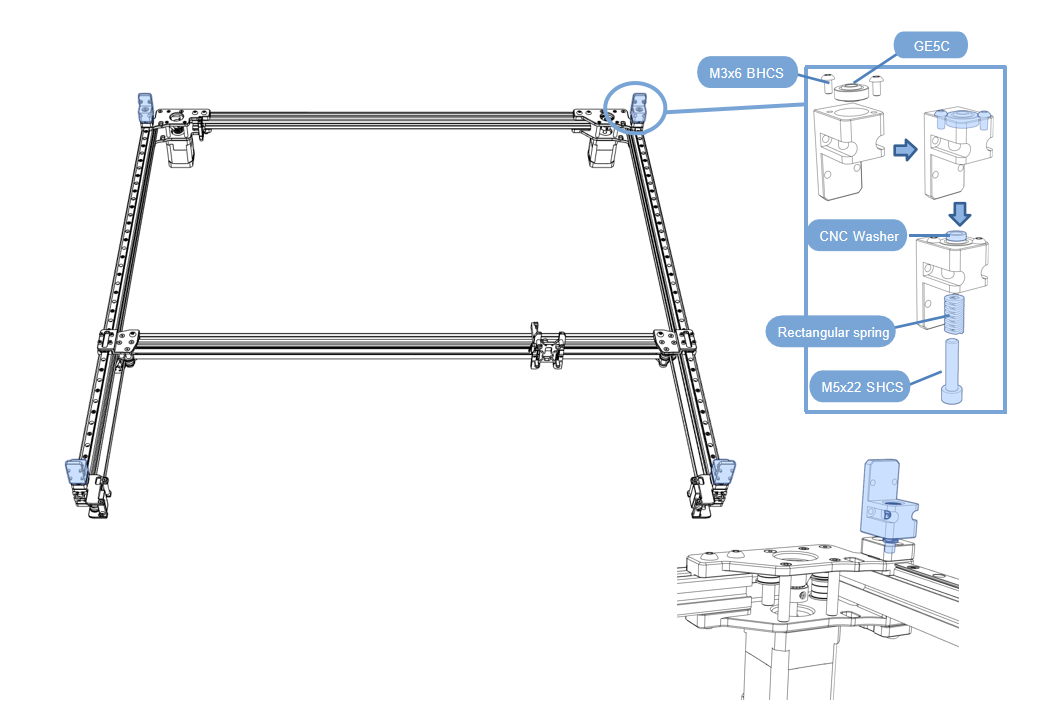

Z-axis connector

- Material preparation

- First install the GE5C fisheye bearing in the connector slot and tighten the screws;

- Use SHCS M5x22 screws to pass through the spring and spacer and lock it to the frame.

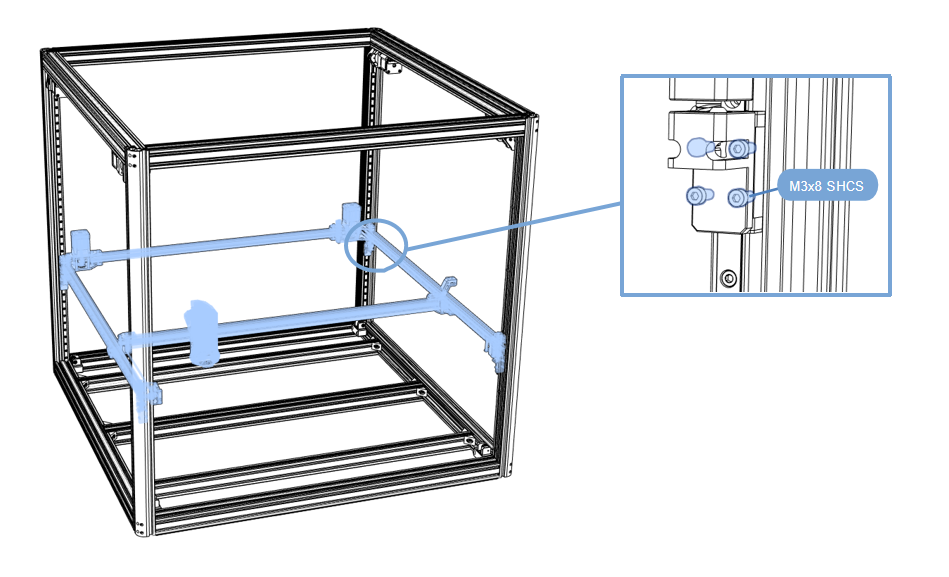

- Tilt the gantry into the frame,Use SHCS M3x8 screws to fix the gantry to the guide rails;

2.3.8 Z-axis Belt

- Pass the belt through the reduction motor and idler pulley as shown, and then fix it to the gantry assembly;

- Tighten all parts screws.

This chapter is assembled

Previous

2.2 Z motor and tensioner assembly

Next

2.4 Hot bed components

Last modified: 2025-08-22

- Prusa mini BMG V1 Extruder

- PRUSA-MK3S-Bear-Upgrade-kit

- Ender3 Y-axis Belt Tensioner

- Ender 5 3D printer Direct Drive Extruder Plate

- Ender3 belt double Z upgrade kit

- Ender 3 3D printer Direct Drive Extruder Plate

- CREALITY X-axis Belt Tensioner

- CREALITY CR10 Y-axis Belt Tensioner

- FLASHFORGE_AD5X_ 3D Printer Enclosure Kit

- FYSETC-QuattroBox

- Adventurer_AD5M_AD5M Pro_AD5X_Light Board Bracket

- Adventurer_AD5M_AD5M Pro_Series Universal Camera

Cables

Others