2.4 Hot bed components

2.4 Hot bed components

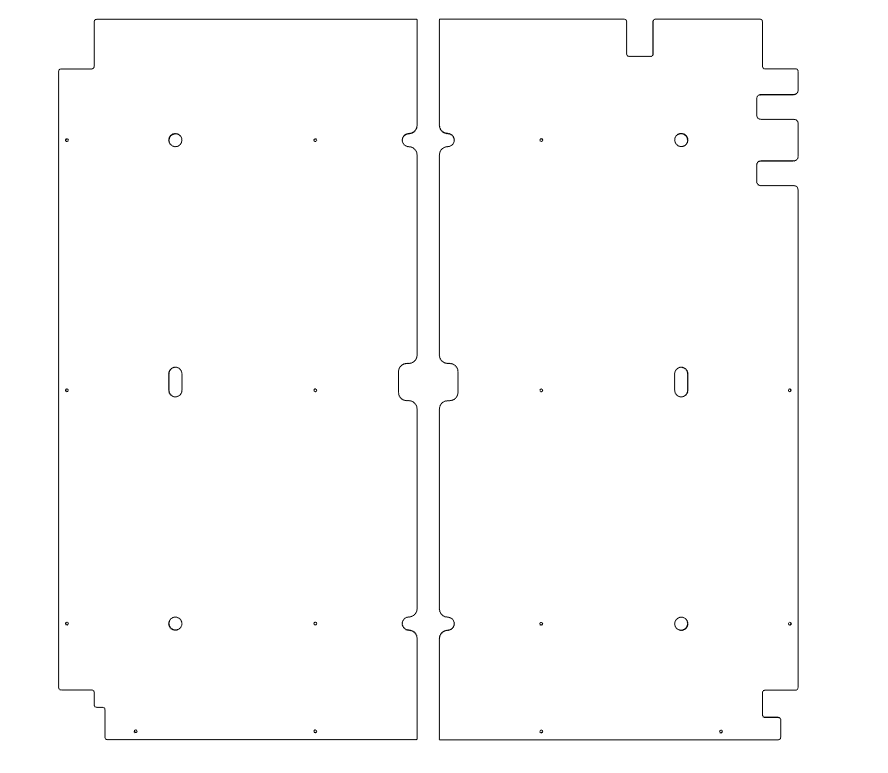

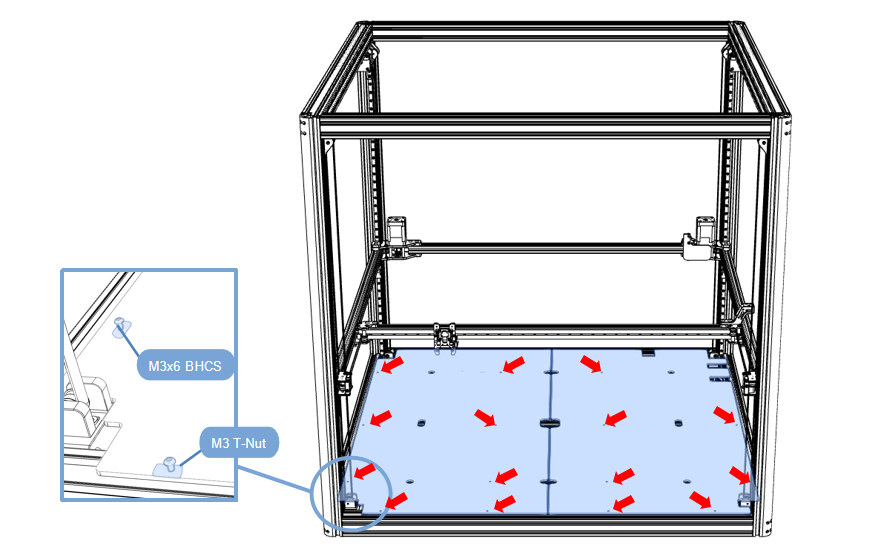

2.4.1 Bottom acrylic plate installation

- Material preparation

- Place the acrylic sheet on the frame base;Use M3x6 BHCS to fix the acrylic sheet to the profile frame;

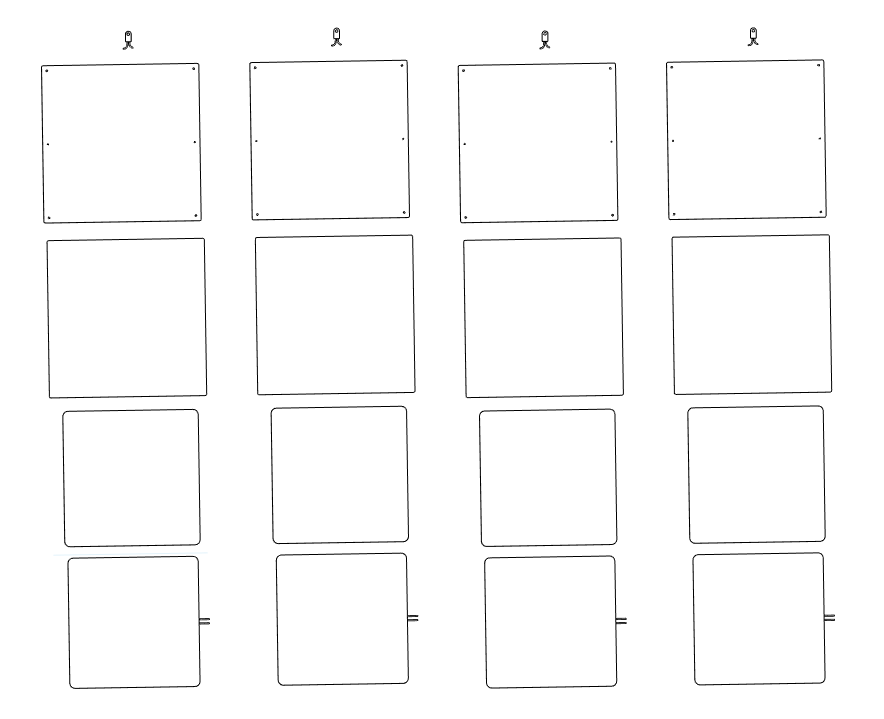

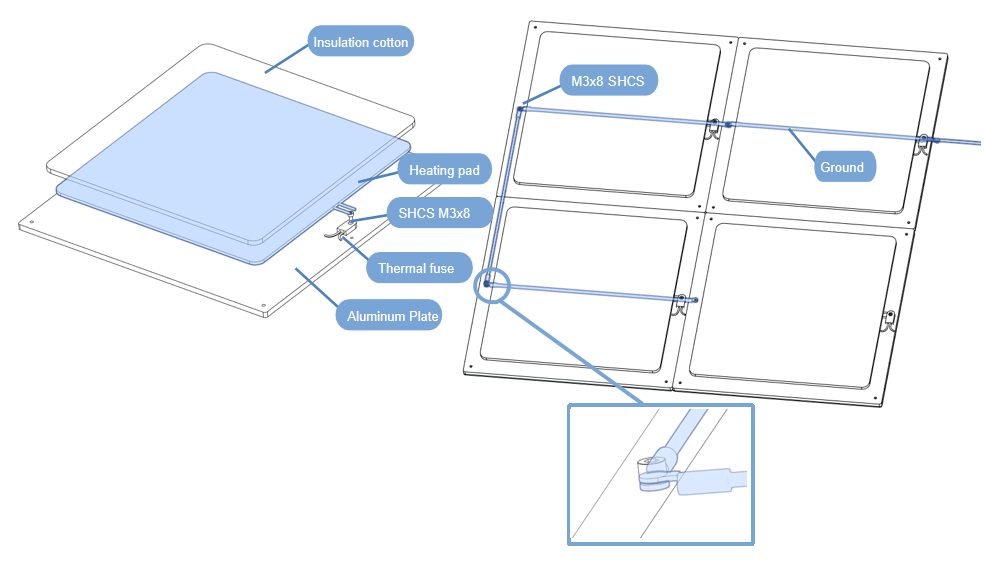

2.4.2 Hot bed assembly installation

-

Material preparation:Aluminum plate, silicone heating pad, Insulation cotton, magnetic stickers, Thermal fuse

Hot bed assembly、Thermal Fuse Installation、Ground wire installation

-

Glue the silicone heating pad to the back of the hot bed in the center;

-

Glue the insulation cotton to the silicone heating pad;

-

Use SHCS M3x8 to fix the thermal fuse to the heat bed;

-

Use SHCS M3x8 on the other side to fix the ground wire;

2.4.3 Hot bed assembly fixing

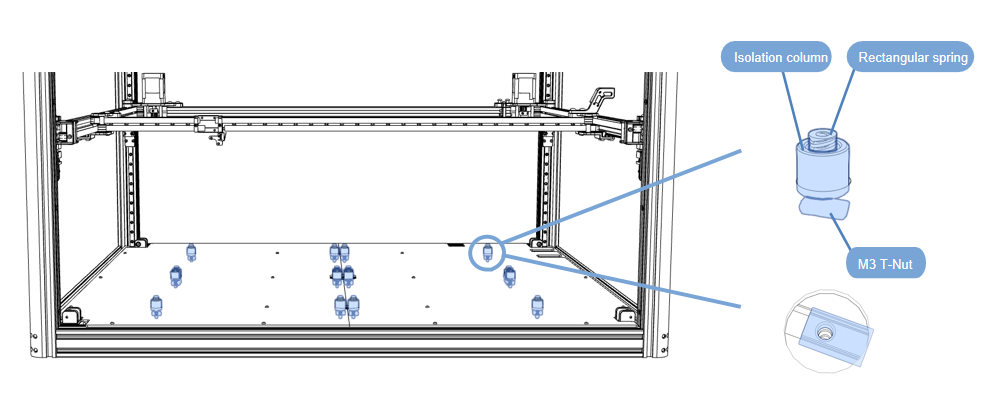

Hot bed isolation column

-

Place an M3 ball nut in the profile groove;

-

Put the spring through the black nylon isolation column and place it in the acrylic plate groove;

-

The hole of the ball nut should be consistent with the hole of the profile;

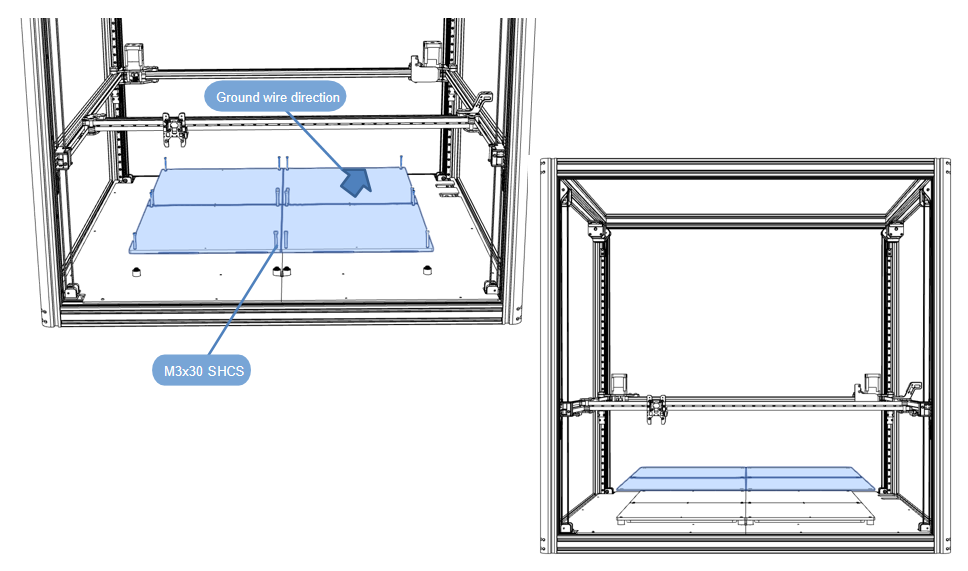

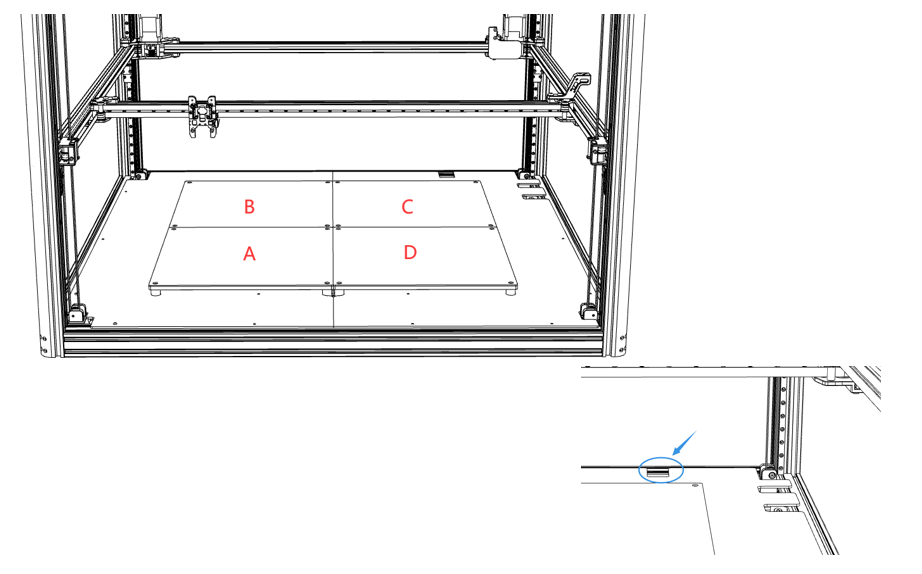

Hot bed fixed

-

Place the 4 hotbeds on the springs;

-

Use the M3x30 SHCS screws to tighten, and screw them to the bottom;

-

Stick the 4 magnetic tiles of the hotbed to the aluminum plate and scrape them flat without bubbles;

-

Pass all the wires of the hot bed through this hole;

-

And mark the power cord and thermistor wire of the hot bed with sticky notes according to the diagram for later wiring;

This chapter is assembled

- Prusa mini BMG V1 Extruder

- PRUSA-MK3S-Bear-Upgrade-kit

- Ender3 Y-axis Belt Tensioner

- Ender 5 3D printer Direct Drive Extruder Plate

- Ender3 belt double Z upgrade kit

- Ender 3 3D printer Direct Drive Extruder Plate

- CREALITY X-axis Belt Tensioner

- CREALITY CR10 Y-axis Belt Tensioner

- FLASHFORGE_AD5X_ 3D Printer Enclosure Kit

- FYSETC-QuattroBox

- Adventurer_AD5M_AD5M Pro_AD5X_Light Board Bracket

- Adventurer_AD5M_AD5M Pro_Series Universal Camera

Cables

Others