H36 Combo V2

Note

- Since there is no 125 degree Celsius USB-HUB chip, the 125 degree Celsius operating environment is limited to CANBUS mode;

- Klipper currently does not support 125 degree Celsius accelerometers, so the 125 degree Celsius operating environment does not include accelerometers. The default version of H36 is ADXL345, which has a maximum operating temperature of 85 degrees Celsius. The 105 degree Celsius ADXL345-EP version is optional, but it is more expensive.

Introduction

H36 Combo V2.0 is a newly designed high temperature tool board running Klipper firmware. Based on STM32G431CBT3, the maximum operating temperature can reach 125 degrees Celsius (CAN only). It also provides two communication methods: CANBUS and USB. The onboard USBHUB has up to two USB interfaces (or one CAN and one USB), which can be used to connect to the IDM Scanner Leveling Sensor camera, etc.

Version Notes

V2.0 (Currently Available)

- Change MCU to STM32G431CBT3

- Reassign pins

- Lead out the header pins for the SWD interface

- When the USB-C port is plugged in, it automatically switches to USB communication.

Featrues

- STM32G431CBT3 MCU, up to 125 degrees Celsius, supports Klipper Firmware

- 6-layer PCB design, all solid capacitors and tantalum capacitors, better heat dissipation

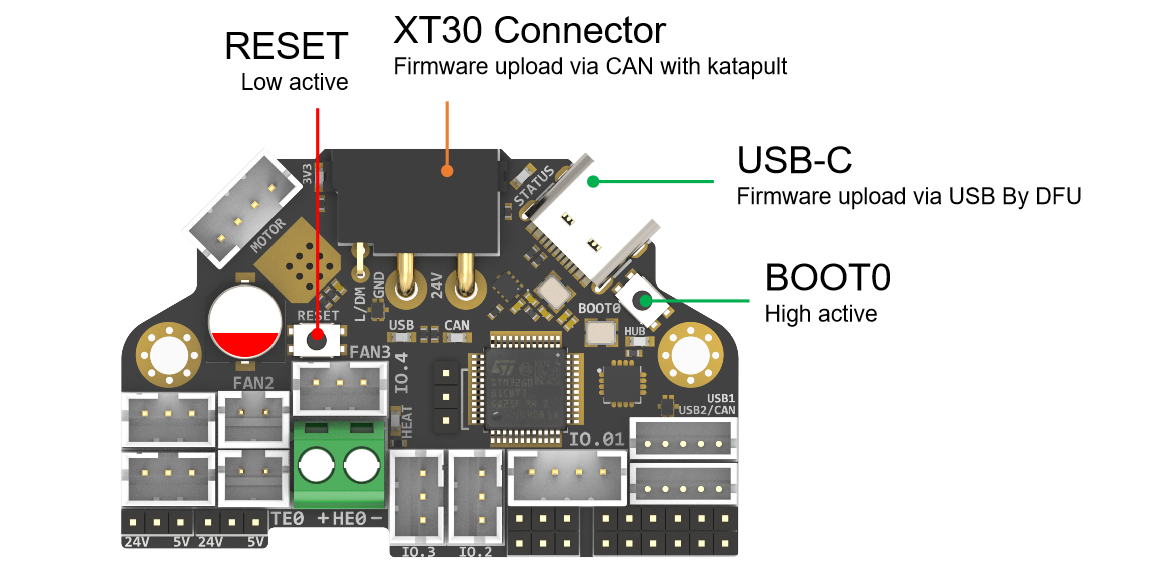

- Onboard RESET and BOOT0 buttons for easy firmware update

- Fan control/heating both use independent high-power MOS, safer and lower heat generation

- Onboard 5V@3A DC-DC, 5V peak load can reach 15W

- XT30 interface, custom cable comes with the board

- Onboard USB2.0 HUB, 3x USB2.0 interface (one of which is connected to MCU)

- Support CAN/USB2.0 connection

- Onboard TMC2209

- 3x 3pin Fans, 3x IO with level converter, 1x RGB,1x Heat, 1x thermistor,1x status LED

- ADXL345 Accelerometer onboard

- USB-C onboard for Firmware update

Application

Print Head with NEMA14/36mm Motor

Hardware specification

| Function | H36 Combo V2.0 | H36 Combo V1 | SB Combo V2 | SB TH CAN V1.3 |

|---|---|---|---|---|

| Microcontroller | STM32G431CBT3 | STM32G0B1T3 | STM32F072CBT6 | STM32F072CBT6 |

| Accelerometer | ADXL345 | ADXL345 | ADXL345 | ADXL345 |

| USB Port | 2 + 1 (For MCU) , Powered by CH334P | 2 + 1 (For MCU) , Powered by CH334P | 2 + 1 (For MCU) + 1(on aux board), Powered by CH334P | 1 |

| CANBUS | 1 + 1 (For MCU) | 1 + 1 (For MCU) | 1 + 1 (For MCU) | 1 |

| Fan | 4 (1x2Pin, 3x3Pin) | 4 (1x2Pin, 3x3Pin) | 3+2 (on aux board) | 2 |

| Heating output | 1 | 1 | 1 | 1 |

| Temperature measurement | 1 (PH2.0 connector) + 1 (on board thermistor) | 1 (PH2.0 connector) + 1 (on board thermistor) | 1 (PH2.0 connector) + 1 (on board thermistor) | 1(PH2.0 connector) |

| Voltage monitoring | 5V, 24V | 5V, 24V | 5V, 24V | - |

| Motor drive | TMC2209 | TMC2209 | TMC2209 | TMC2209 |

| Signal input and output | 5 (PH2.0) + 7 (pin header) | 5 (PH2.0) + 7 (pin header) | 3 | 3 |

| RGB light strip control | default 2, up to 5 | default 2, up to 5 | 1 + 1 (on aux board) | 1 |

| Aux Board support | No | No | Yes | No |

| Onboard mounting nut | No | No | Yes | No |

Operating limits

Waining

The following values are tested at room temperature of 25°C. Please do not keep the highest peak value running for a long time!

Please do a good job of cooling the board in a higher temperature environment.

| Stepper drivers | Up to 2.0A peak current |

|---|---|

| Mosfets Outputs | HE0 up to 5A Max, Fan up to 0.5A each |

| Input power voltage | 11V to 24V for VIN up to 10A Max |

| Inputs/Outputs | Signal 20ma maximum, RGB power supply 1.5A total maximum |

| 5V and 3.3V current limit | 5V@3A Max,3.3V@0.8A Max |

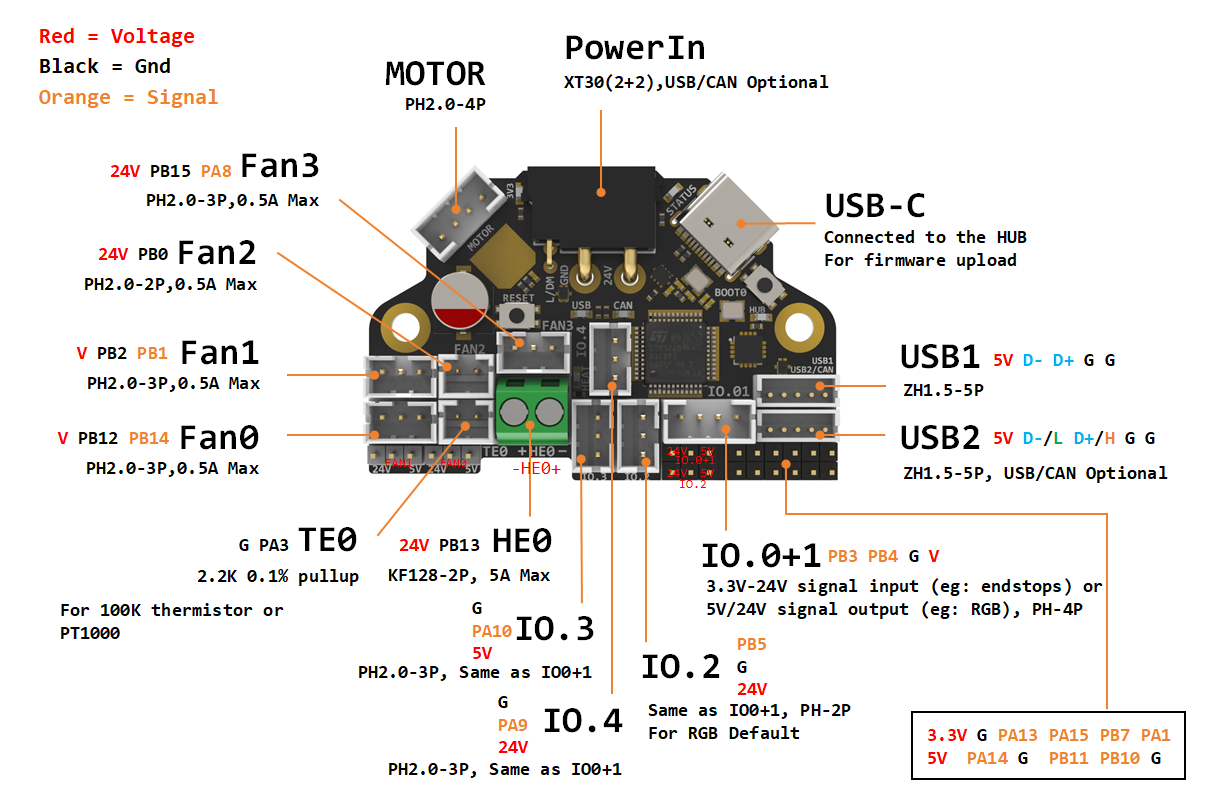

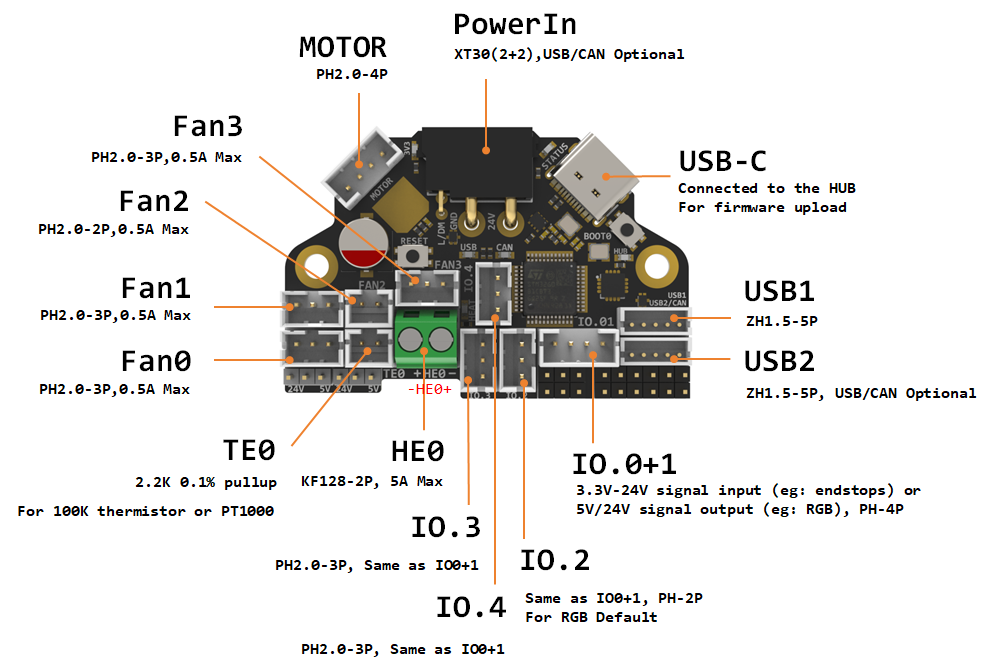

Physical Connections

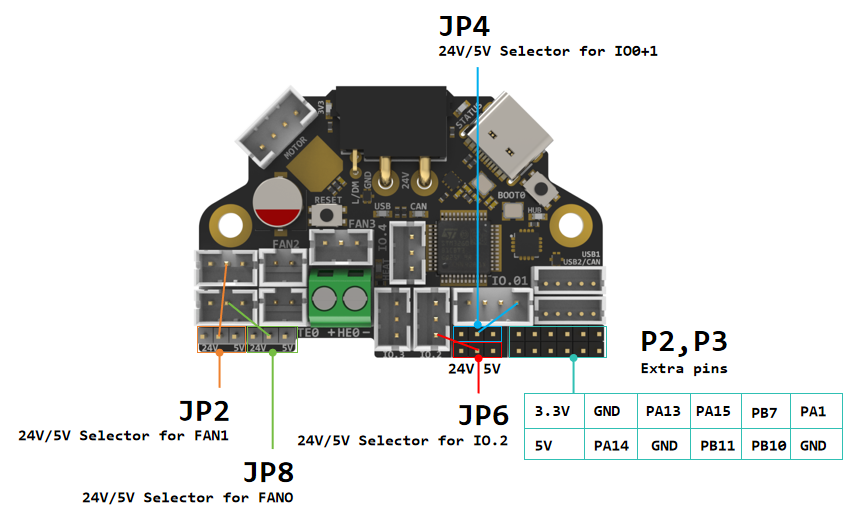

Pin Out

Thanks to Esoterical for creating this image.

IO.0: PB3

IO.1: PB4

IO.2: PB5

IO.3/RGB0: PA10

IO.4/RGB1: PA9

# IO.0 - IO.4 with level conversion (pull-up), it can be used as 5V/24V level input and output!

FAN0: PB12

FAN0_TACH: PB14

FAN1: PB2

FAN1_TACH: PB1

FAN2: PB0

FAN3: PB15

FAN3_TACH: PA8

Heat: PB13

Thermistor (2.2k pull up): PA3

Driver_EN: PC14

Driver_DIR: PC15

Driver_STEP: PB9

Driver_UART: PB6

Driver_DIAG: PA13

ADXL345

spi_bus: spi1

adxl345_cs_pin: PA4

adxl345_spi_software_sclk_pin: PA5

adxl345_spi_software_miso_pin: PA6

adxl345_spi_software_mosi_pin: PA7

CAN_RX: PA11

CAN_TX: PA12

Thermistor next to TMC2209 (4.7k pull up) : PA0

CAN USB switch: PA2

# logic Low = COM to A PORT CANBUS

# Logic High = COM to B PORT USBDescription of Connections:

IO.0 and IO.1 are located in the same connector and can be used as XY endstops, and IO.2 can be used as a probe. In addition, IO.0 - IO.5 have level conversion (with pull-up resistors) , IO.01, IO.2 have voltage selectors (5V or 24V) pin header, IO.3 IO.4 have voltage selectors (5V or 24V) pads. All the IOs can be used as inputs or outputs, such as RGB ,Servo, Endstops, and can be configured according to your other needs.

| Connector | Pin | Default function | Altermate |

|---|---|---|---|

| Power Input | USB (PA11,PA12) CANBUS (PA11,PA12) |

Power and communication input, USB 2.0 and CANBUS are optional, Determined by the level of PA2. | |

| Fan0 | FAN0: PB12 FAN0_TACH: PB14 |

Mosfet Output, For 2/3 pins Fan, Default voltage = Depending on voltage selector. (Header voltage selector) |

|

| Fan1 | FAN1: PB2 FAN1_TACH: PB1 |

Mosfet Output, For 2/3 pins Fan, Default voltage = Depending on voltage selector. (Header voltage selector) |

|

| Fan2 | PB0 | Mosfet Output, For 2 pins Fan, Default voltage = VIN. (Pad voltage selector) |

|

| Fan3 | FAN3: PB15 FAN3_TACH: PA8 |

Mosfet Output, For 2/3 pins Fan, Default voltage = VIN. (Pad voltage selector) |

|

| IO.0+1 | PB3, PB4 | Digital Input, For X Y endstop, Micro switch or Hall (Header voltage selector) |

Digital Output |

| IO.2 | PB5 | Digital Input, For Z probe, Proximity switch or Klicky, etc. (Header voltage selector) |

Digital Output |

| IO.3/RGB0 | PA10 | 5V Digital Output, 5V power supply default, For 5V WS2812/SK6812 RGB/Servo (Pad voltage selector) |

Digital Input |

| IO.4/RGB1 | PA9 | 5V Digital Output, 24V power supply default, For 24V WS2812/SK6812 RGB/Servo (Pad voltage selector) |

Digital Input |

| USB1 | USB2.0 | J2 | |

| USB2/CAN | USB2.0 or CANBUS 2.0, USB 2.0 and CANBUS are optional,Determined by the level of PA2. | J1 | |

| TE0 | PA3 | ADC input, 2.2K pull-up, head temperature measure | |

| HE0 | PB13 | Mosfet Output, Heating rod control, 5A Max | |

| MOTOR | For two-phase stepper motor, | ||

| USB1, USB-C connector | Connected to the CH334PHUB chip, up to 4 USB2.0 devices (MCU/USB1/USB2/USB3) |

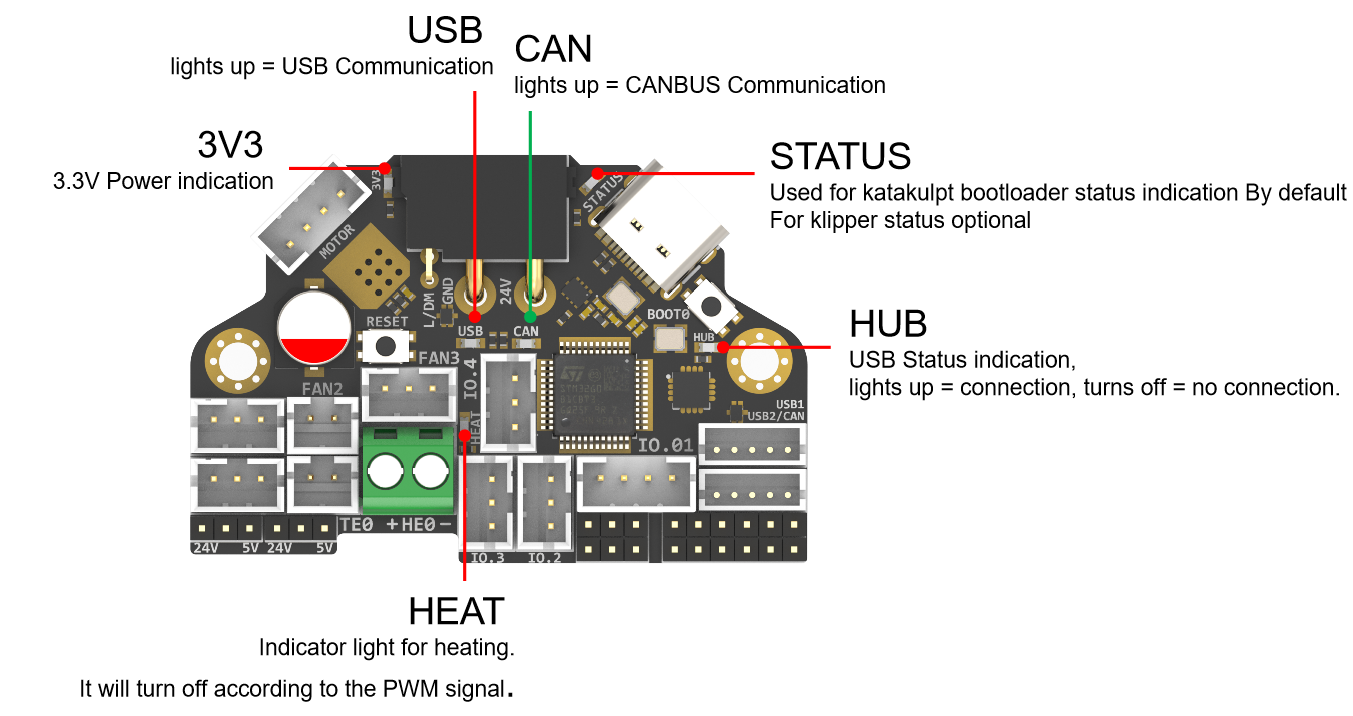

LED indications:

| LED name | Indicate | Remark |

|---|---|---|

| 3V3 | Lights up: Power supply OK. Turns off : Power supply failure. 3.3V is obtained by converting 24V to 5V through DC-DC and then to 3.3V through LDO, so there may be a short circuit/open circuit in 24V/5V/3.3V. |

Red |

| HUB | Lights up: The USB has at least one connection. Turns off: The USB has no connection. |

Red |

| STATUS | When using katakulpt- Blinking: Entering download mode;Off/Always on: Not in download mode, the status is generally determined by config; The LED is controlled by PC13 and lights up at a high level. For customized usage, please refer to julianschill/klipper-led_effect |

Red |

| HEAT | Lights up or flashes according to the heating PWM | Red |

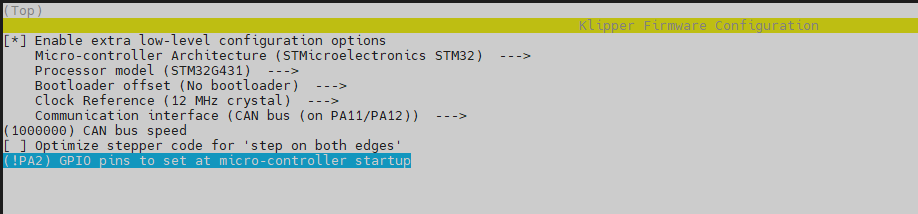

| USB | USB communication Indicate, use "PA2" at the config menu | Red |

| CAN | CAN communication Indicate, use "!PA2" at the config menu | Green |

USB / CAN selection

XT30 and USB2/CAN both use CAN to communicate refer to the instructions below for connecting the H36 via CAN.

XT30 and USB2/CAN both use USB to communicate refer to the instructions below for connecting the H36 via USB.

Header Jumpers:

IO.0+1 , IO.2 , Fan0 , Fan1 can select the power supply voltage through the jumper cap.

As shown in the figure, the two pins on the left are connected together for 24V, and the two pins on the right are connected together for 5V.

NOTE

Please note that if these interfaces are used as outputs, the high-level voltage of the output is consistent with the voltage selected by the jumper. Please make sure that your peripherals can withstand the range. Generally speaking, only SSR in the accessories of 3D printers can withstand 9-36V control voltage.

Communication

Connect to Pi

H36 combo V2 can be connected to Pi via USB or CANBUS. Select by PA2, refer to USB / CAN selection.

Via CAN

Since the Raspberry Pi does not have a CANBUS interface, it is usually connected only after the CANBUS interface is expanded through an expansion chip. Commonly used ones include the MCP2518 SPI to CAN module (CanHat), USB to CAN module (eg: UCAN), Klipper USB to CAN Bridge Mode, and a Linux host computer with a native CAN interface (eg: CM68).

Via USB

When using USB connection, you can use the adapter board we provide to directly connect to the USB interface of PI.

Firmware Guide

Firmware configuration and compilation

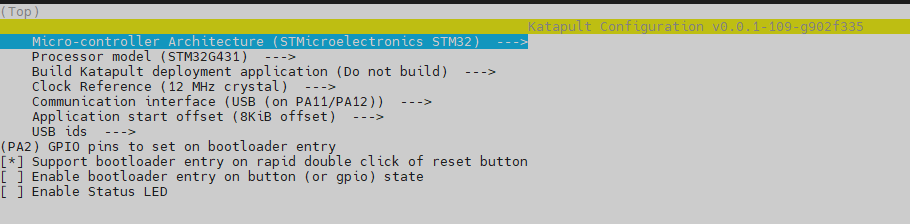

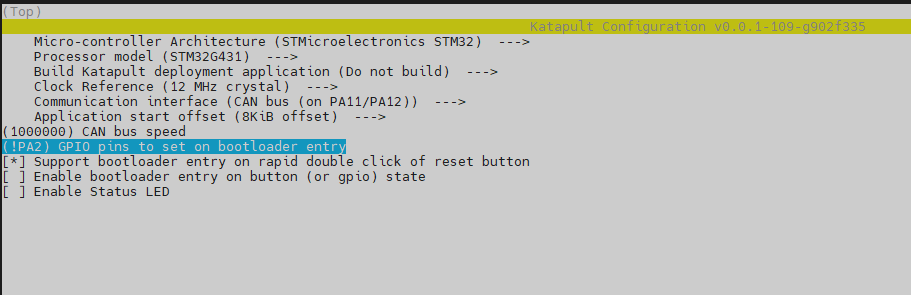

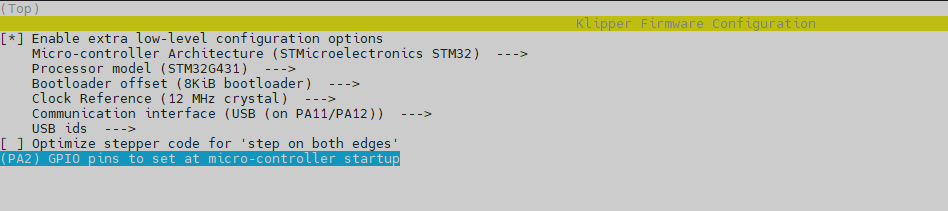

With Katapult Bootloader

If you need to use a bootloader, we recommend using katapult. The following is not configured for reference:

For katapult use, refer to: https://github.com/Arksine/katapult

cd ~/katapult

make menuconfig

make flash FLASH_DEVICE=0483:df11

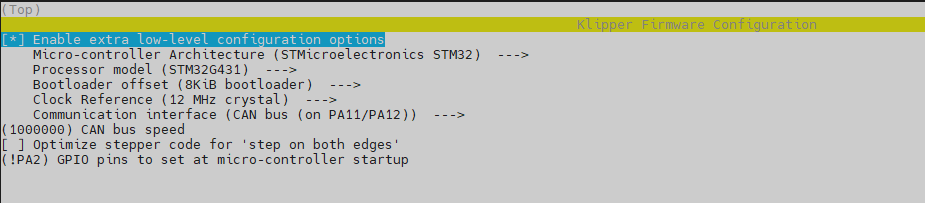

cd ~/klipper

make menuconfig

make

cd ~/katapult/scripts

#when using CAN communication

python3 flashtool.py -i can0 -f ~/klipper/out/klipper.bin -u <uuid>

#when using USB communication

python3 flashtool.py -d <serial device> -b <baud_rate> -f ~/klipper/out/klipper.bin

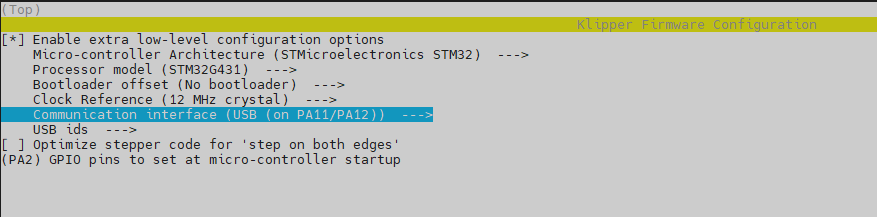

Klipper with nobootloader

H36 uses the bootloader-free mode by default, and the configuration is as follows:

Firmware upload

Before executing the following commands, you need to enter DFU mode before you can compile and burn the firmware. As shown in the figure above,

- press and hold BOOT0,

- then press the RESET button for one second,

- then release RESET,

- wait for 3 seconds,

- and release BOOT0.

Use " lsusb" to check if a DFU device appears. If yes, upload firmware. If no, repeat the above steps.

make flash FLASH_DEVICE=0483:df11under katapult Klipper uploading, Please refer to:

https://github.com/Arksine/katapult?tab=readme-ov-file#uploading-klipper

Attachments and others

2D,3D , SCH and config template file, please go to our github:

https://github.com/FYSETC/H36_Combo_V2

How to buy

Technical Support Channel

- Prusa mini BMG V1 Extruder

- PRUSA-MK3S-Bear-Upgrade-kit

- Ender3 Y-axis Belt Tensioner

- Ender 5 3D printer Direct Drive Extruder Plate

- Ender3 belt double Z upgrade kit

- Ender 3 3D printer Direct Drive Extruder Plate

- CREALITY X-axis Belt Tensioner

- CREALITY CR10 Y-axis Belt Tensioner

- FLASHFORGE_AD5X_ 3D Printer Enclosure Kit

- FYSETC-QuattroBox

- Adventurer_AD5M_AD5M Pro_AD5X_Light Board Bracket

- Adventurer_AD5M_AD5M Pro_Series Universal Camera

Cables

Others