S2210

1.Product Introduction

The S2210 driver module is designed based on Trinamic's new generation chip TMC2210. Thanks to the brand-new architecture and process, its peak current can reach 3.0A, its continuous current can reach 2.1A, and it can withstand an input voltage up to 36V. TMC2100. All its functions only need to configure the IO hardware, no software programming is required.

2.Features

- Hardware compatible with StepStick and Pololu A4988 Stepper Driver

- Components on bottom PCB side for better heat emission

- Automatic standby current reduction

- StealthChop2™ silent PWM mode- for quiet operation and smooth motion

- SpreadCycle - highly dynamic motor control chopper

- Drive capability up to 2.1A (RMS) & 3.0A(PEAK) coil current

- Step/Dir interface with microstep interpolation (up to 256 microsteps)

- Input microsteps 1-64 optional

- Configuration via CFG pins

- Supply voltage 4.5-36V

3. Specifications Comparison

| Model | TMC2100 | TMC2209 | TMC2210 |

|---|---|---|---|

| Interface | Step/Dir | Step/Dir | Step/Dir |

| Configuration | CFG Pins | UART | CFG Pins |

| Native Microsteps | up to 1 ⁄ 16 | up to 1 ⁄ 32 | up to 1 ⁄ 64 |

| microPlyer Microsteps | 1 ⁄ 256 | 1 ⁄ 256 | 1 ⁄ 256 |

| Logic Supply Voltage (VIO) | 3.0 - 5.25V | 3 - 5.25V | 2.2 - 5V |

| Motor Supply Voltage (VM) | 4.75 - 46V | 4.75 - 28V | 4.5 - 36V |

| Motor Phase Current max | 1.2A RMS, 1.7A Peak | 2A RMS, 2.8A Peak | 2.1A RMS, 3.0A Peak |

| Internal V- Regulator | enabled | enabled | enabled |

| RDSon (typ. at 25°C) | LS 400mΩ & HS 500mΩ | 170mΩ | 230mΩ |

| Rsence | 0.11Ω | 0.11Ω | chip built-in |

| stealthChop (quiet) | yes | yes | yes |

| spreadCycle | yes | yes | yes |

| coolStep | no | yes | no |

| stallGuard | no | yes | no |

| dcStep | no | yes | no |

4. Pin Functions

| Pin | Function |

|---|---|

| Power Supply | |

| GND | Ground |

| VM | Motor Supply Voltage |

| VIO | Logic Supply Voltage |

| Motor Outputs | |

| B1 | Motor Coil 1 |

| B2 | Motor Coil 1 |

| A2 | Motor Coil 2 |

| A1 | Motor Coil 2 |

| Control Inputs | |

| STEP | Step-Signal Input |

| DIR | Direction-Signal Input |

| CFG Pins | |

| EN | Enable Motor Outputs: GND=on, VIO=off, OPEN=Auto-Power-Down |

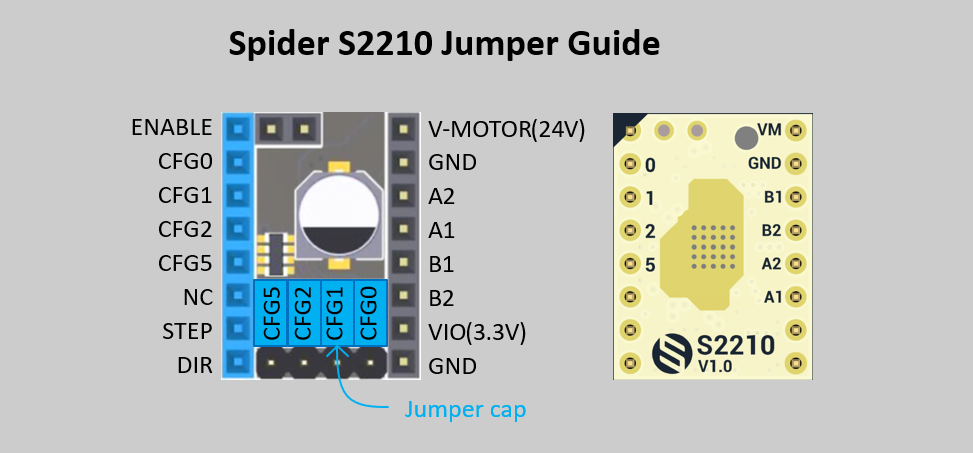

| CFG0 | Onboard pulled down,CONFIGURATION OF MICROSTEP RESOLUTION FOR STEP INPUT |

| CFG1 | Onboard pulled down, CONFIGURATION OF MICROSTEP RESOLUTION FOR STEP INPUT |

| CFG2 | Chip internal pull-up,CONFIGURATION OF RUN CURRENT IRUN (ALONG WITH IREF RESISTOR), DO NOT CHANGE DURING OPERATION |

| CFG5 | Chip internal pull-up,SELECTION OF CHOPPER MODE |

| Index | Open drain index pulse output indicating, microstep 0 position of coil B. |

| Error | Open-drain error output. Use external pullup resistor. In system reset state, this pin is actively pulled low to indicate reset condition to external controller. |

| NC | No pins connected |

| Onboard Jumper | |

| CFG3 | Onboard pulled down,CONFIGURATION OF RUN CURRENT IRUN (ALONG WITH IREF RESISTOR), DO NOT CHANGE DURING OPERATION |

| CFG4 | Onboard pulled down,DIGITAL CURRENT SCALE (MAY BE CHANGED DURING OPERATION) |

| CFG6 | Onboard pulled up,CONFIGURATION OF HOLD CURRENT REDUCTION |

| CFG7 | Onboard pulled down,CONFIGURATION OF HOLD CURRENT REDUCTION |

5. Interface Resources

Wiring Diagram

5.1 Motor Current Setting

The current setting method of TMC2210 is slightly different, which is determined by CFG2 and CFG3 and the resistance value connected to IREF. Before we start, we need to clarify several relationships:

- IRUN: The current when the motor rotates, set by CFG2 and CFG3 and the resistance value connected to IREF.

- IHOLD: The current at which the motor is held still, set by CFG6 and CFG7.

- IPEAK: Also known as Imax or Full Scale Current, the driver chip provides peak current (the peak value of the sine wave)

- IRMS: The effective value of the current provided by the driver chip (the effective value of the sine wave, usually is about the peak value/1.41)

5.1.1. Setting the Full Scale Current Range

The full scale current IFS is a peak current setting. It is selected with an external reference resistor and the two configuration pins CFG2 and CFG3

Three different full-scale current ranges can be configured through the pins with the same reference resistor to adapt to different motor sizes and applications. This is needed to benefit from the best possible current control resolution.

Connect a reference resistor RREF from IREF to GND. Together with pins CFG3 and CFG2, the full scale current range IFS is set based on the external resistor .

The equation below shows the full-scale current IFS as a function of the RREF shunt resistor connected to pin IREF and the configuration pin setting. The proportionality constant KIFS is defined by the CFG2 and CFG3 setting. The external resistor RREF can range between 12kΩ and 60kΩ.

I_{FS}=K_{IFS}(KV)/R_{REF}(kΩ)

Table 9. IFS Full Scale Current Range Settings (Example for RREF = 12KΩ)

| PIN CONFIG IN STANDALONE MODE | PIN CONFIG IN STANDALONE MODE | KIFS (A x kΩ) | MAX FS SETTING | TYPICAL RDS(ON) (HS + LS) | NOTES |

|---|---|---|---|---|---|

| 1 | 1 | 36 | 3A | 0.23Ω | Optimized efficiency for motors and applications rated up to 2.1A rms |

| 1 | 0 | 36 | 3A | 0.23Ω | Optimized efficiency for motors and applications rated up to 2.1A rms |

| 0 | 1 | 24 | 2A | 0.27Ω | Optimized efficiency for motors and applications rated up to 1.4A rms |

| 0 | 0 | 11.75 | 1A | 0.40Ω | Optimized efficiency for motors and applications rated up to 0.7A rms |

5.1.2. Setting the Rref

IFS Full Scale RMS Current in Ampere (A RMS) based on CFG2/CFG3 Pin Settings and different RREF

| RREF(kΩ) | KIFS = 24 |

|---|---|

| 12 | 1.41 |

| 15 | 1.13 |

| 18 | 0.94 |

| 22 | 0.77 |

| 27 | 0.63 |

| 33 | 0.51 |

| 39 | 0.44 |

| 47 | 0.36 |

| 56 | 0.30 |

According to the circuit of the module, we perform this demonstration calculation:

Rref: The resistor connected to the IREF pin, which consists of a 12K resistor and a maximum 50K adjustable resistor. The factory value of the adjustable resistor is generally located in the center, which is 25K, and all default Rref=37K.

CFG3 is pulled down by default, which is equivalent to the GND level, and CFG2 is high when no external level is connected, so the default KIFS=24KV.

I_{FS}=K_{IFS}(KV)/R_{REF}(kΩ)=24(KV)/37(KΩ)=0.65A

5.1.3 Hold Current (IHOLD) Reduction Configuration

CFG7(Onboard pulled down)/CFG6(Onboard pulled up): CONFIGURATION OF HOLD CURRENT REDUCTION

| CFG7 | CFG6 | HOLD CURRENT REDUCTION |

|---|---|---|

| GND | GND | No hold current reduction. IHOLD = IRUN |

| GND | VCC_IO | Reduction to 50%. IHOLD = 1/2 IRUN |

| VCC_IO | GND | Reduction to 25%. IHOLD = 1/4 IRUN |

| VCC_IO | VCC_IO | Reduction to 12.5%. IHOLD = 1/8 IRUN |

5.1.4 Digital Current Scale Configuration

CFG4(Onboard pulled down ): DIGITAL CURRENT SCALE (MAY BE CHANGED DURING OPERATION)

| CFG4 | CURRENT SCALE |

|---|---|

| GND | I = 75% of full scale current IRUN |

| VCC_IO | I = 100% of full scale current IRUN |

5.3 Microsteps Setting

Microsteps Resolution Configuration for the Step Input,CFG1(Onboard pulled down )CFG0(Onboard pulled down ),So the default is 8 microsteps.

| CFG1 | CFG0 | microsteps | Interpolation | Mode |

|---|---|---|---|---|

| GND | GND | 8 | 256 | StealthChop2 |

| GND | VIO | 16 | 256 | StealthChop2 |

| VIO | GND | 32 | 256 | StealthChop2 |

| VIO | VIO | 64 | 256 | StealthChop2 |

6. Other Configs

6.1 Chopper Mode Selection

CFG5 (Chip internal pull-up): SELECTION OF CHOPPER MODE

| CFG5 | CHOPPER MODE |

|---|---|

| GND | SpreadCycle operation |

| VCC_IO | StealthChop2 operation |

7. How to config the code in klipper/marlin

S2210 only needs to configure the corresponding STEP, DIR, EN pins on the software, no additional configuration is required.

It is worth noting that the subdivision parameters on the software need to be consistent with the jumpers on the hardware.

For example, the X-axis configuration in klipper is as follows:

[stepper_x]

## Connected to X-MOT (B Motor)

step_pin: PE11

dir_pin: PE10

enable_pin: !PE9

rotation_distance: 40

microsteps: 8

full_steps_per_rotation:200 #set to 400 for 0.9 degree stepper

endstop_pin: ^PB14

position_min: 0

##--------------------------------------------------------------------

position_endstop: 300

position_max: 300

##--------------------------------------------------------------------

homing_speed: 25 #Max 100

homing_retract_dist: 5

homing_positive_dir: trueAny configuration such as [tmc2209 stepper_x] is no longer needed.

NOTE:

- Pay attention to the direction.

- The heat sink is directly attached to the PCB.

- The motor direction is the opposite of 4988 and 8825. If you want to replace the 4988 directly, please adjust the firmware or adjust the motor connection.

Documents

SCH: https://github.com/FYSETC/S2210/blob/main/TMC2210 V10.pdf

Datasheet: https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC2210_datasheet_rev1.pdf

Shop

Tech Support

Please submit any technical issue into our forum

- Prusa mini BMG V1 Extruder

- PRUSA-MK3S-Bear-Upgrade-kit

- Ender3 Y-axis Belt Tensioner

- Ender 5 3D printer Direct Drive Extruder Plate

- Ender3 belt double Z upgrade kit

- Ender 3 3D printer Direct Drive Extruder Plate

- CREALITY X-axis Belt Tensioner

- CREALITY CR10 Y-axis Belt Tensioner

- FLASHFORGE_AD5X_ 3D Printer Enclosure Kit

- FYSETC-QuattroBox

- Adventurer_AD5M_AD5M Pro_AD5X_Light Board Bracket

- Adventurer_AD5M_AD5M Pro_Series Universal Camera

Cables

Others